Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur belt capstans ensure the stability of line speed and are highly reliable in long runs as well as with high pulling forces. The stable line speed minimizes cable diameter variations.

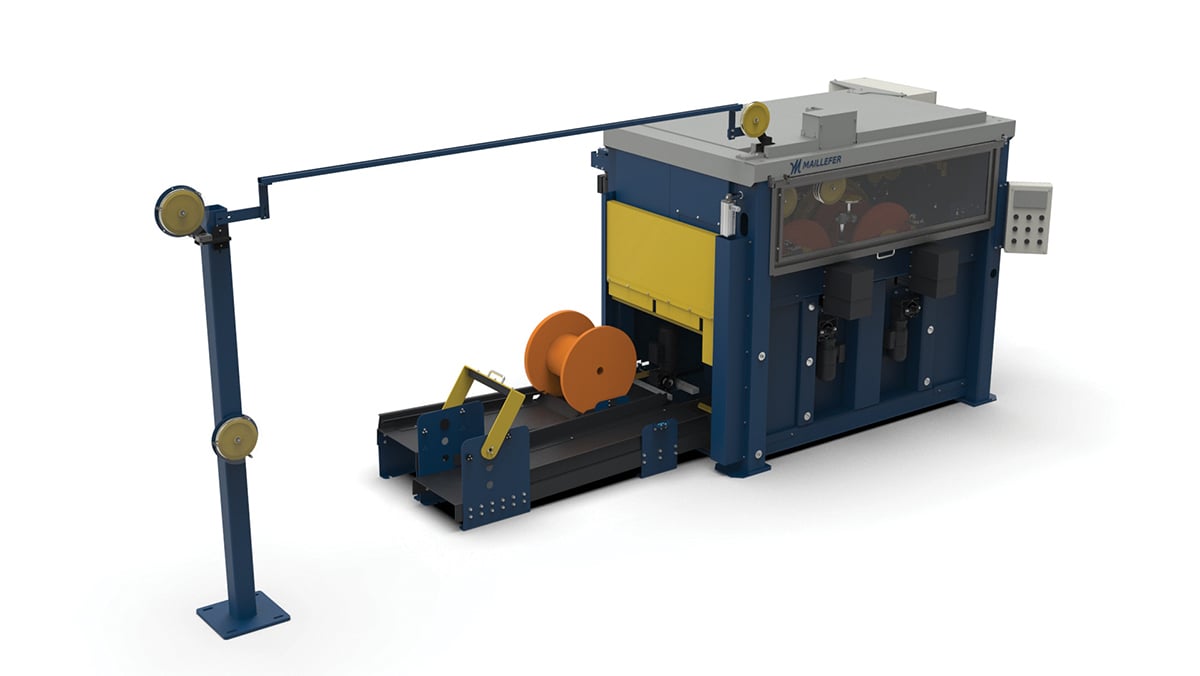

Belt Wrap Capstan BWC 800 is used in cable production lines to run the cable or the conductor at a desired line speed. An accurate speed is achieved with the AC motor, which is controlled by a frequency converter. The converter is located in the drive cabinet.

Pneumatic cylinders press the belt against the drive wheel, and the drive wheel provides the pulling force. The pressing force is adjusted from the belt wrap capstan control panel where the pressure gauges are located. The belt is opened and closed from the same control panel.

| Cable diameter, max. | 40 mm |

| Pulling force, max. | 640 N |

| Line speed, max. | 500 m/min |

| Dimensions L x W x H | 2600 x 1331 x 1500 mm |

Exact values depend on the assembly.

12.11.2025

Vice President Philippe Moeschler shares insights on innovation, sustainability, and customer care as Maillefer showcases its latest technologies at K 2025. Read more

7.11.2025

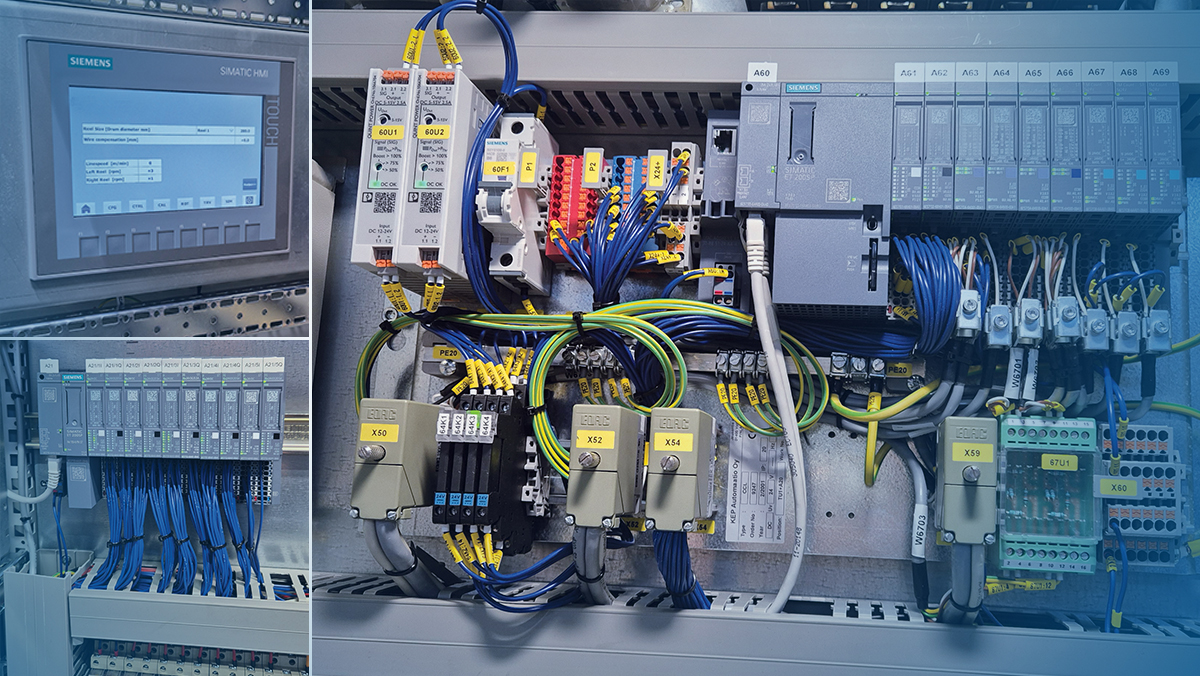

Replace the outdated analog cards of your durable EKP take-up. Overcome the maintenance challenge. Our PLC replacement kit helps you ensure the move to the digital world. Read more

30.10.2025

The robust EKP take-ups keep improving over time. The new generation covers today’s broad range of wire & cable applications. It’s a durable addition to any extrusion line, both new and existing. Read more

15.10.2025

This multi-layer PEX / PE-RT extrusion line maybe a bit past, yet it is performing even better than the day it was delivered. Thanks to the attentive services of our agent, Montenegro S.r.l. Read more

9.10.2025

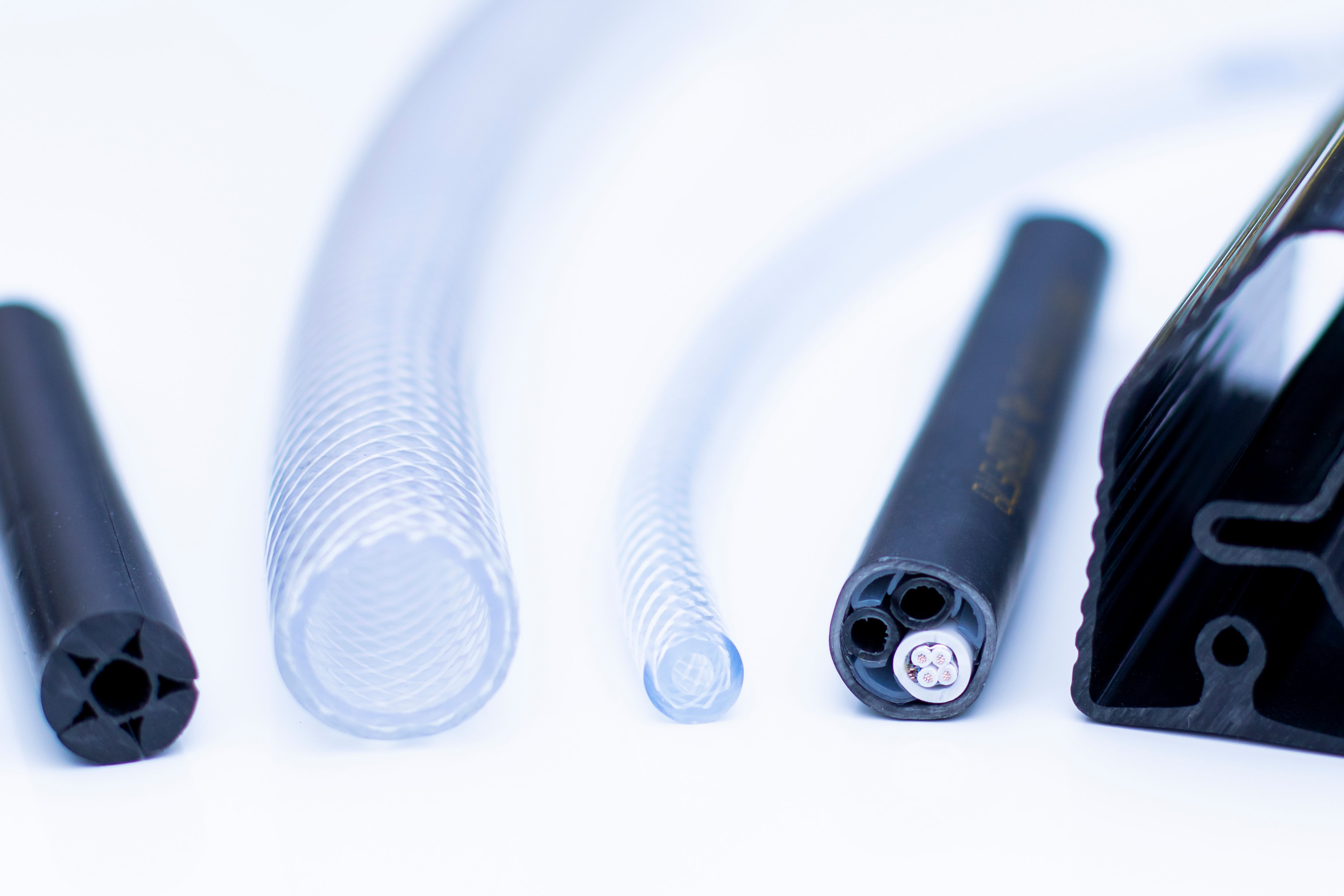

Toppi is a family name as well as a brand of no-nonsense entrepreneurship which started over 70 years ago. The privately owned Finnish company, located in Espoo, specializes in producing high-quality plastic hoses, tubes, profiles and cables for industrial and consumer needs. Family members stay dedicated to every aspect of Toppi operations, including plans for growth. Read more

3.10.2025

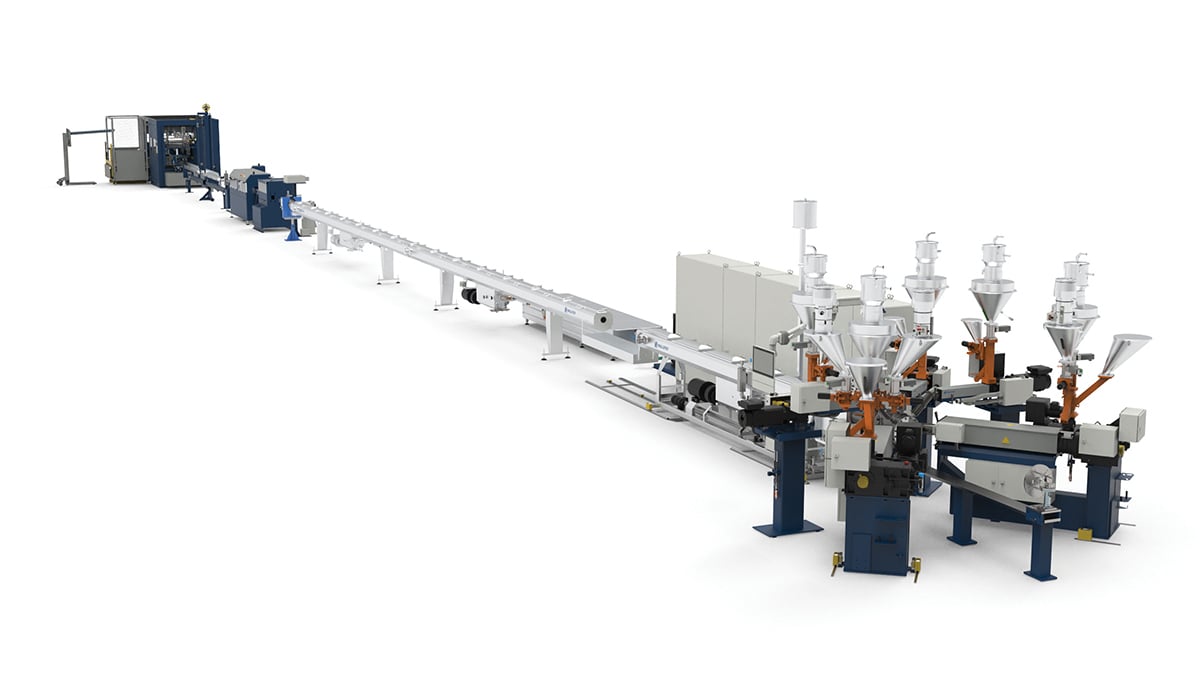

Redefine heating & plumbing pipe extrusion with a complete system that boosts efficiency, precision, and scalability. The PXL multi-layer line is a step above the rest. Read more

3.10.2025

Synergies and partnerships translate to more extrusion systems, and now include multi-lumen, TPE materials, and triple layer co-extrusion alongside our classic IV tube lines. Read more