Reka Cables specializes in manufacturing high quality cables fitted for the challenging Nordic circumstances. Their success in the cable business is built on the right technology as well as the right competencies to get the most out of chosen technologies. Cost and quality should never be compromised in cable production.

Reka Cables is one of the biggest cable producers in Finland with an annual turnover of EUR 85 million. To its customers, Reka offers a wide variety of installation and power cables from low voltage to 170 kilovolts. Reka’s main markets are in the Nordic countries and the Baltics with sales subsidiaries in Sweden, Norway, Denmark, Estonia and St. Petersburg, Russia.Co-operation with Maillefer began already in the late 90's, when Reka decided to expand from building wire and low voltage to medium and high voltage cable production.

Reka and Maillefer share a keen interest in improving cable production operations at all levels. High quality is a must, and it has to be achieved with the minimum cost of ownership. The companies engage in joint product testing on Reka’s production lines, especially in extrusion and crosslinking processes. Maillefer’s newest screw and crosshead designs, for example, have improved Reka’s production processes significantly. For Reka, this has been a perfect way to stay ahead of competitors.

At the moment, there is a huge need to find the most sustainable solutions. Thanks to close cooperation with Maillefer’s competent specialists, Reka has managed to achieve short delivery times and flexibility in production as well as savings in material, energy and operation costs.

“We feel that sustainability can always be improved throughout the production lifecycle. In that respect, Maillefer has been a great business partner,” sums up Jari Henttonen, Reka’s Production Director.

25.2.2026

Maillefer Empowers Partners to Achieve Unmatched Performance Through Innovative and Sustainable Solutions Read more

10.2.2026

For over 50 years, Maillefer has led Heating & Plumbing extrusion technology — delivering reliable, high-performance systems for modern, efficient production. Read more

29.1.2026

The 2026 Budget Law (Law No. 199 of 30 December 2025) introduces new hyper-amortization rules for investments in capital goods made between 1 January 2026 and 30 September 2028, in line with the Transition 4.0 and 5.0 tax credit frameworks. Read more

20.1.2026

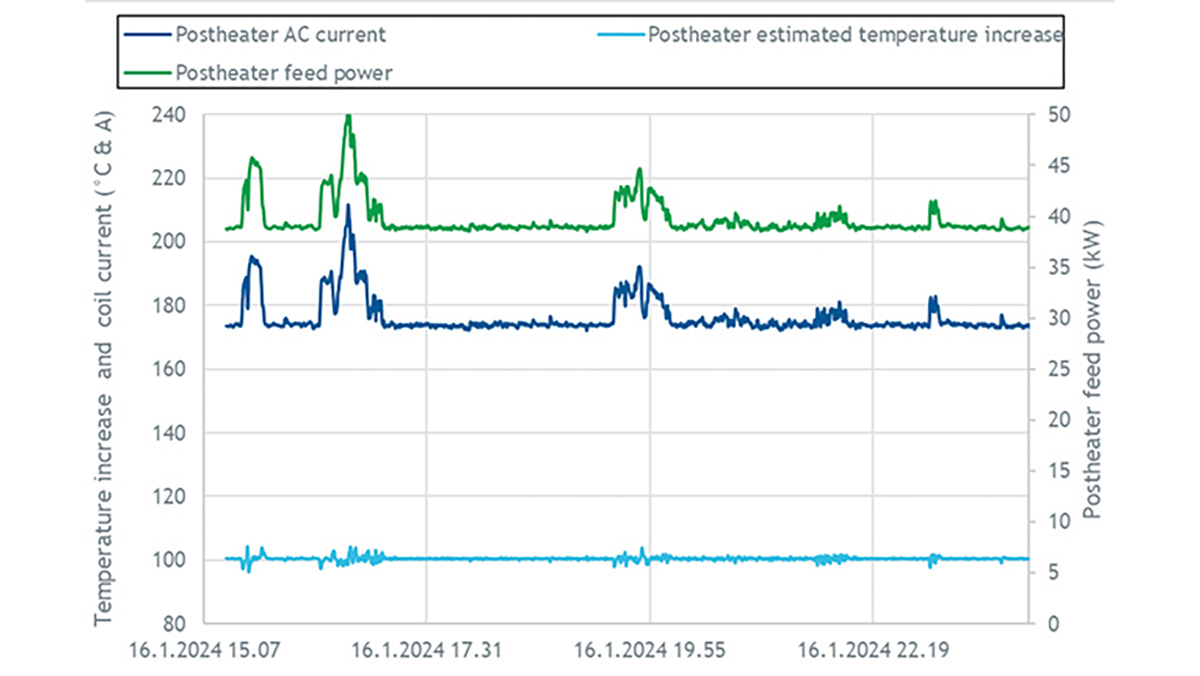

Move forward in curing optimization. Intelligent induction gets you consistent conductor temperature and superior cable quality. The system self-adapts to conductor temperature in real time. Read more

8.1.2026

Smarter upgrades mean stronger performance. Maillefer’s new KWB coiler and CMC cutter bring precision, safety, and efficiency to augment the potential of your extrusion line. Read more

18.12.2025

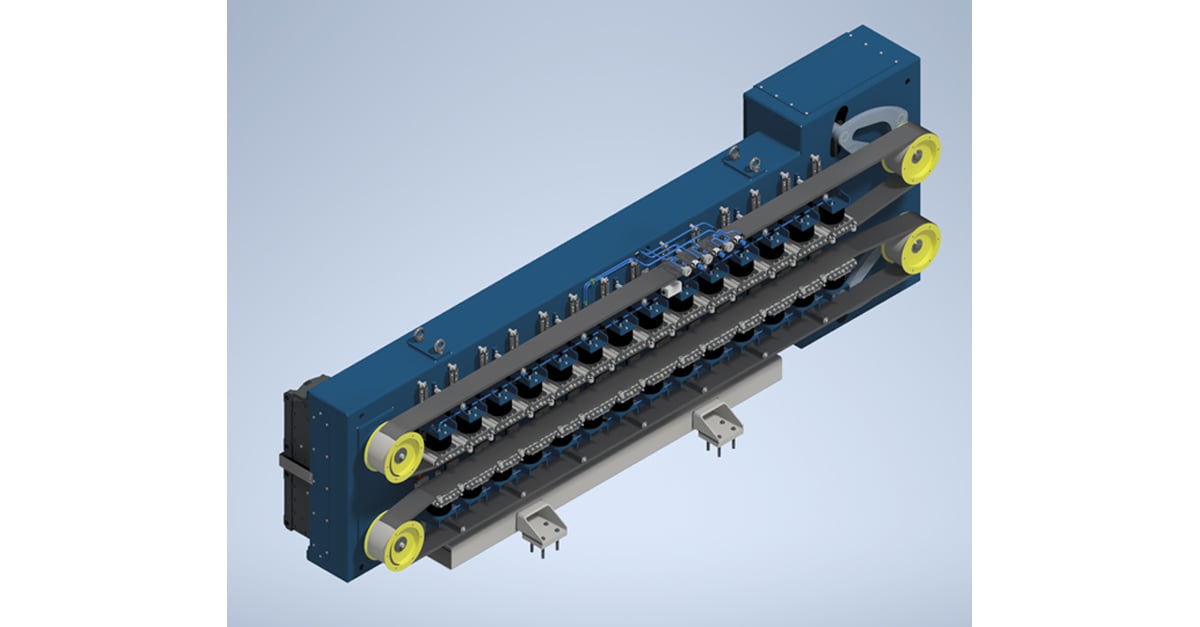

As cable sizes grow, Maillefer’s new heavy-duty caterpillars deliver unprecedented pulling power. Designed for the toughest cables, they boost traction, efficiency, and performance. Read more

15.12.2025

For 125 years, Maillefer has innovated in industry. From modest origins to a global leader, the company continues to drive technology, sustainability, and customer success. Read more

24.11.2025