Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

Phipps Bend Industrial Park<br />

402 Phipps Bend Road

TN 37873 Surgoinsville

Tel: +1 423 817 2440

Fax: +1 423 212 0131

om;a.c;rus;efe;ill;/ma;jonMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troThe MXC range of air-cooled extruders ensures high productivity and reliable operation over long periods. The forced feeding design results in a stable quality melt with high output across a wide processing window.

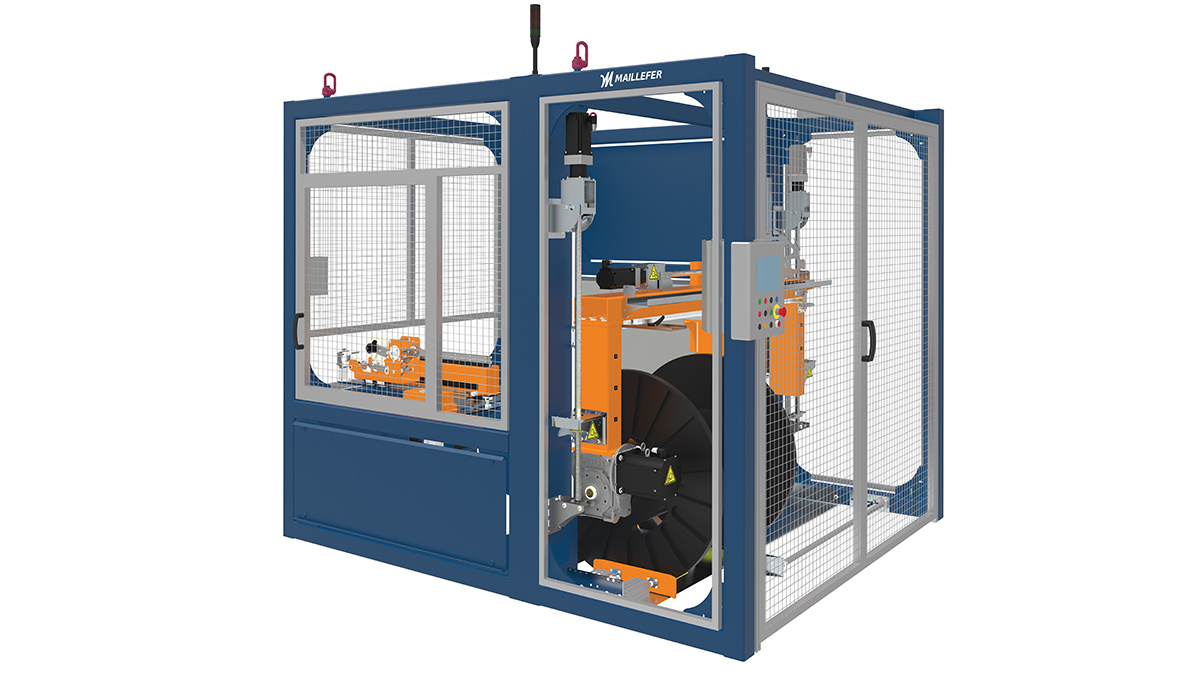

Our Air Cooled Extruder MXC 100-30D is based on the well-known and proven extrusion technology of Maillefer. The extruder suits many standards and applications in cable, tube and conduit manufacturing. A unique screw and barrel combination, perfected through theoretical studies, computer simulations and know-how accumulated over decades, guarantees high, stable and linear output with low melt temperature.

The design of the extruder is compact with all main components on a single base frame. This construction provides a rigid and stable support for barrel and gearbox. Proven design and reliability are the main features of the low noise gearbox. Splash lubrication ensures minimum maintenance requirements.

Extraction of the screw from the barrel can be done by attaching a simple but effective mechanism (supplied with the extruder) to the gearbox. The force necessary to push the screw out of the barrel is provided by the extruder motor itself. No special mechanical skills are required of the operator to carry out this task.

| Screw diameter | 100 mm |

| Screw operation length | 30D |

| Max. screw speed | 96 rpm |

Exact values depend on the assembly.

17.7.2024

The KWS, KWI for profile, and TUT join the family of coilers / reelers / take-ups best suited for winding pipe, tube and profile. They offer the right fit for the right job. Read more

10.7.2024

This new compact take-up is designed especially for small fiber optic jacketing lines. The machine is optimized for light weight and flexible products like drop cables and premise cables. Read more

10.7.2024

Maillefer is proud to drive changes taking place in our industry. It feels like magic, filled with excitement, when innovations are at their best! Master more with less. Read more

3.7.2024

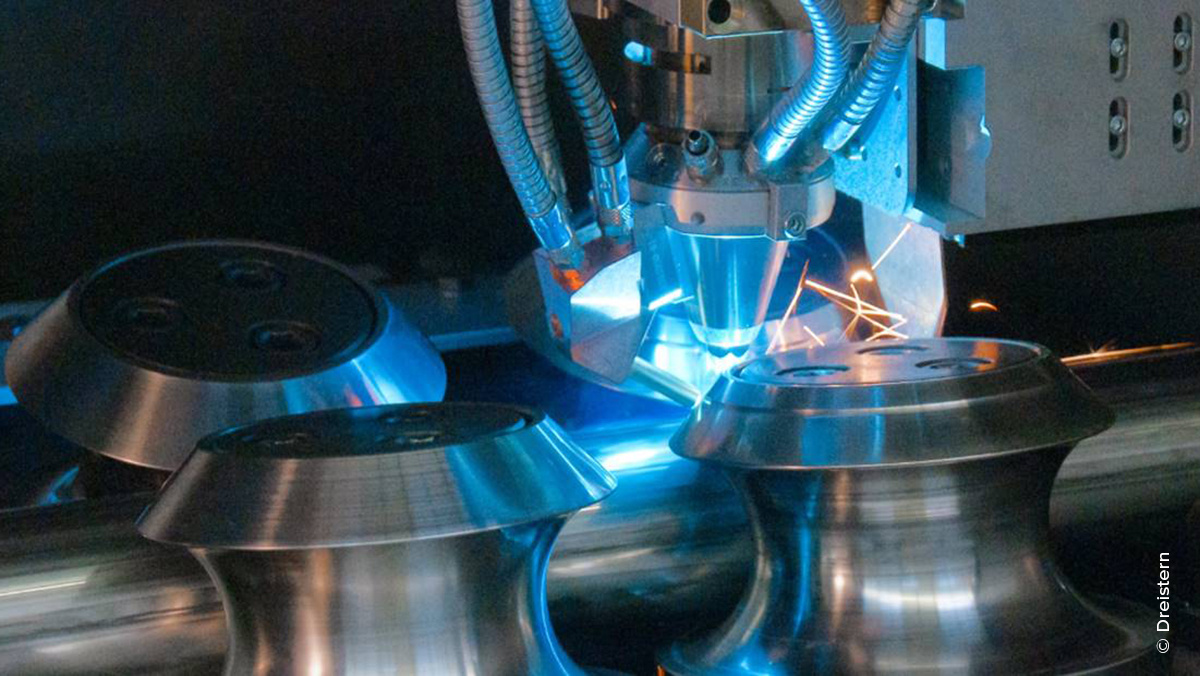

Maillefer proposes both aluminum butt welding techniques in its offering. Ultimately, it’s the customer’s local conditions and particular situation that helps make the choice. Read more

19.6.2024

An extrusion process involves various factors to minimize environmental impact and resource consumption. Maillefer favors exchange that focus on maximizing efficiency. Read more

12.6.2024

Critical S5 PLC components are proving to be nearly impossible to find anywhere on the world’s markets. Are you ready to face the increasing probability of a breakdown? Read more

6.6.2024

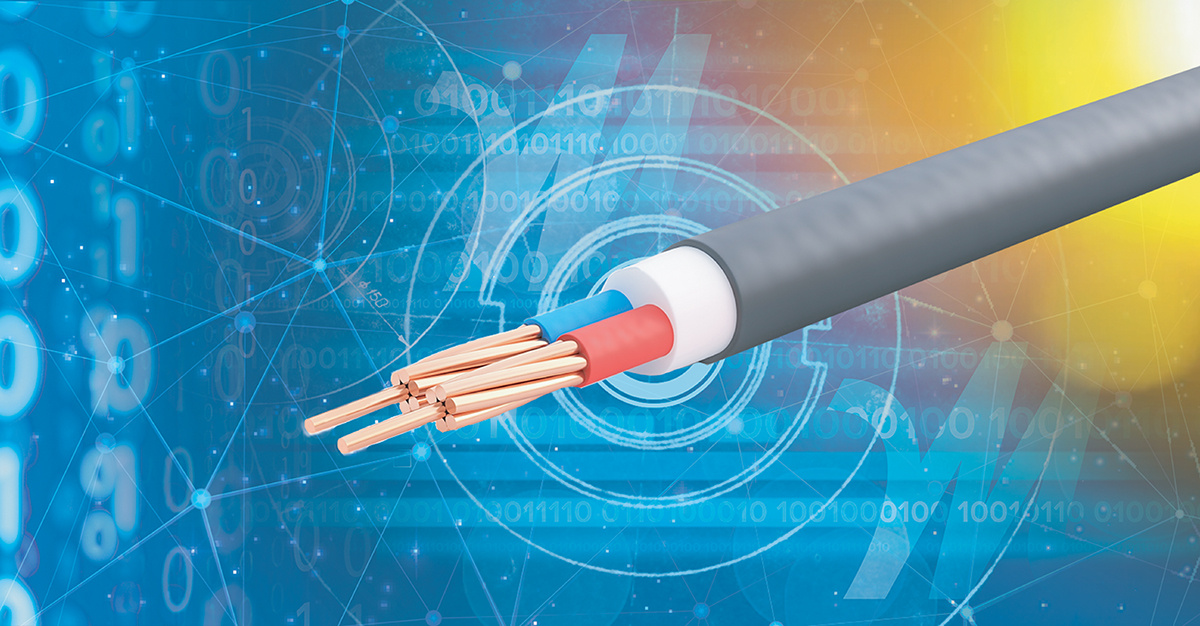

Stack-up your chances when co-extruding. Formulations and rheology are a moving target. An analytical approach means offering more than just extrusion equipment. Read more

29.5.2024

Be ready with this perfect solution for medium- and high-voltage PP insulated cable production. Short residence times and streamlined flow channels are just the beginning of what this crosshead offers. Read more