Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

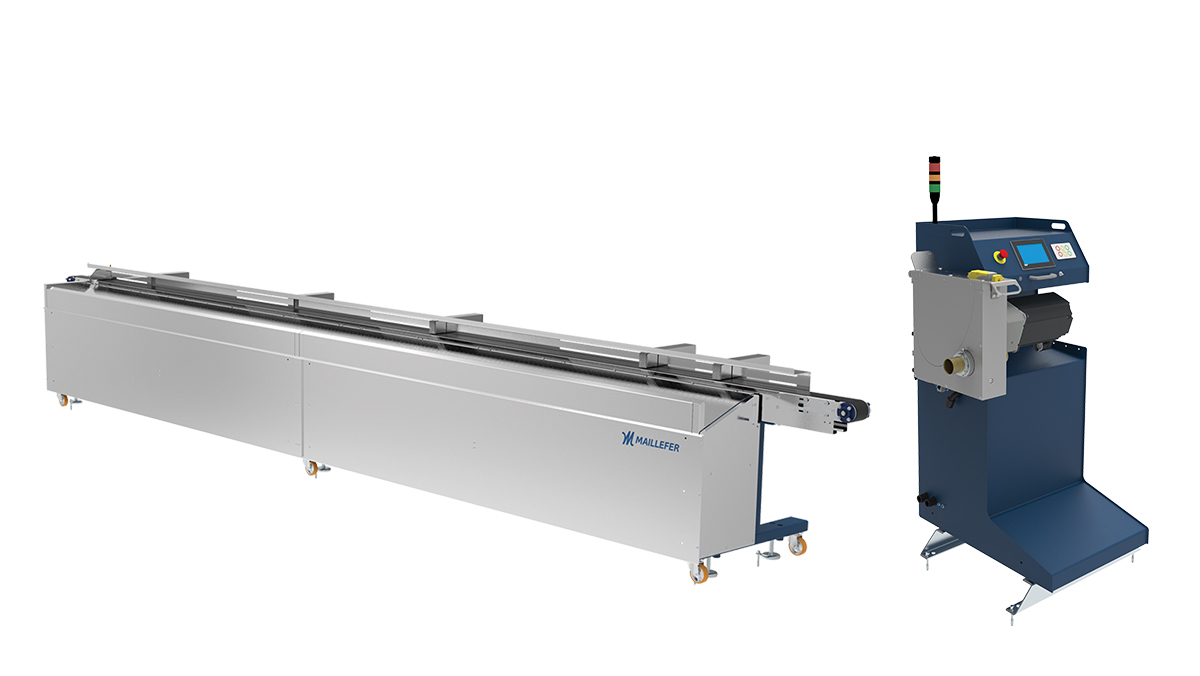

net;ns.;tio;olu;ons;usi;xtr;y/e;troThe NMA range of air-cooled extruders ensures high productivity and reliable operation over long periods.

Our Air Cooled Extruder NMA 30-24D is based on the well-known and proven extrusion technology of Maillefer. The extruder suits many standards and applications in cable, tube and conduit manufacturing. A unique screw and barrel combination, perfected through theoretical studies, computer simulations and know-how accumulated over decades, guarantees high, stable and linear output with low melt temperature.

The design of the extruder is compact with all main components on a single base frame. This construction provides a rigid and stable support for barrel and gearbox. Proven design and reliability are the main features of the low noise gearbox. Splash lubrication ensures minimum maintenance requirements.

Extraction of the screw from the barrel can be done by attaching a simple but effective mechanism (supplied with the extruder) to the gearbox. The force necessary to push the screw out of the barrel is provided by the extruder motor itself. No special mechanical skills are required of the operator to carry out this task.

| Screw diameter | 30 mm |

| Screw operation length | 24D |

| Max. screw speed | 270 rpm |

Exact values depend on the assembly.

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more