Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troThe new generation EKP 630 is available with new lines but also ideal as retrofit into existing ones. It is designed to work independently from line controls, therefore providing an easy fit into any configuration.

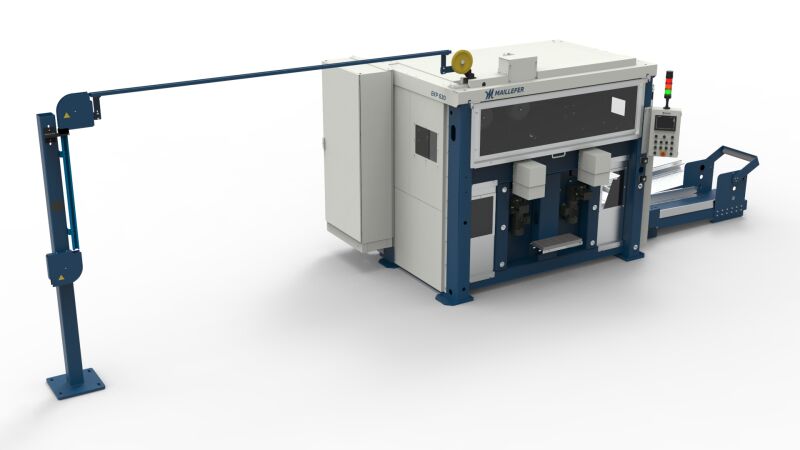

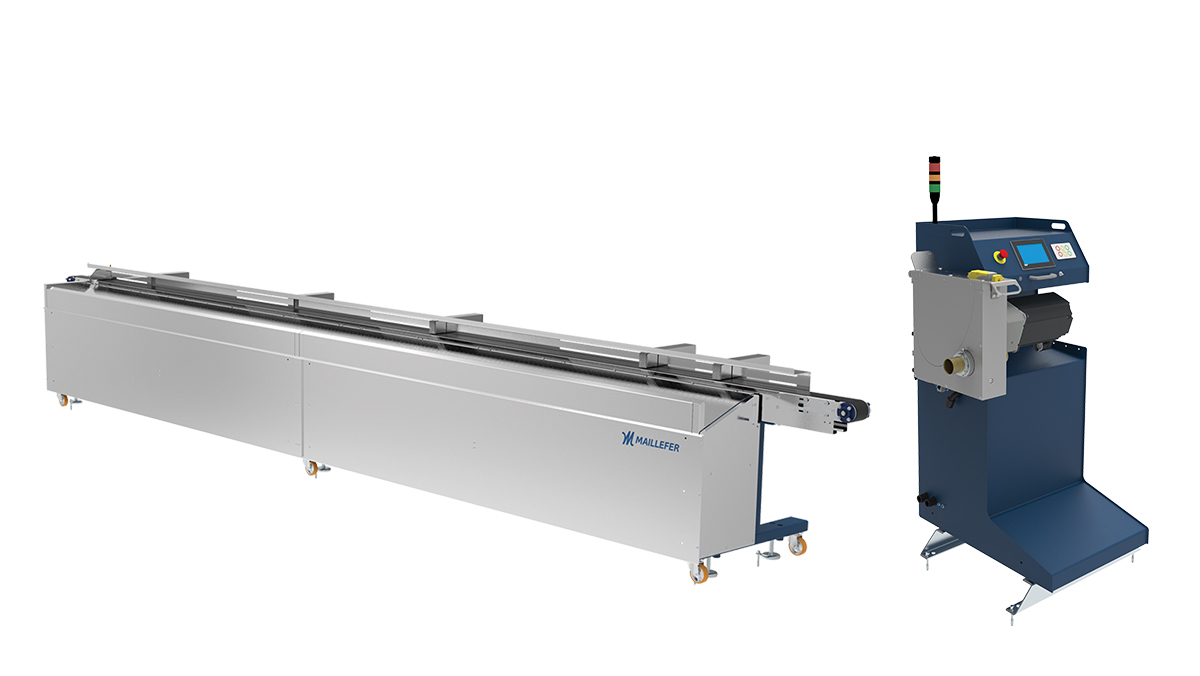

The automatic dual take-up EKP 630 is designed to serve versatile applications in telecom and special cable extrusion lines.

EKP 630 works independently from the line controls, therefore providing easy adaptation to any configuration as result. The control cabinet of the take-up is integrated to the machine frame leading to minimized space requirement and quick commissioning. The take-up is controlled with combination of touch screen and push-buttons located in the control panel at the front side of the machine. The take-up is equipped with self-diagnostics feature for quick and improved troubleshooting.

The take-up speed is automatically controlled to match the speed of the line product. Constant product tension is ensured with pneumatic dancer installed inside of the take-up. The spooling tension can be set through the control panel or remotely from the line control. The reels are rotated with AC motors. The automatic traverse control compensates eventual minor reel dimension variations while ensuring even spooling result. The EKP 630 wire catching device is spring loaded and opened by a pneumatic cylinder. This ensures that the catching device is cleaned before the next reel change - a solution that enables a reliable wire change-over within the whole speed range. The automatic reel change starts after wire change-over but can also be started manually when necessary.

| Reel flange diameter (mm) | 300-510 or 400-630 |

| Reel overall width (mm) | 100-475 |

| Max. full reel weight (kg) | 350 |

| Cable Outer Diameter (mm) | 0.5-5.0 |

| Tension Range (N) | 4-50 |

| Line Speed | max. 2500 m/min |

| Dimensions L x W x H | 5000 x 2490 x 2520 mm |

Exact values depend on the assembly.

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more