Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

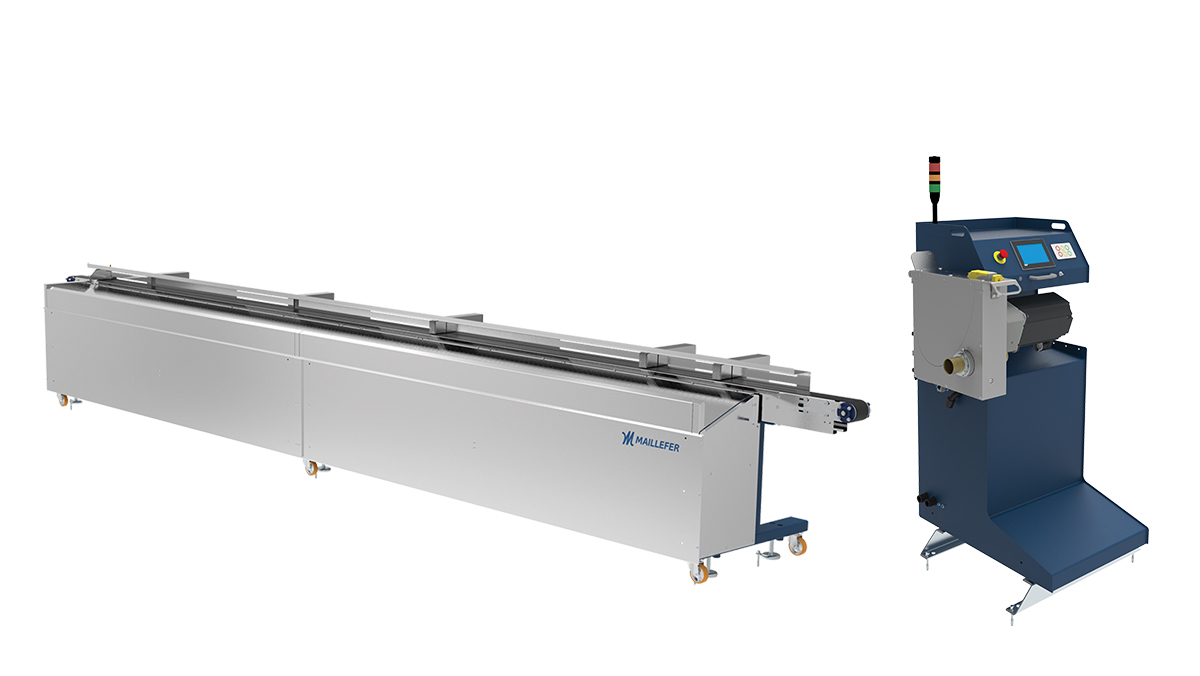

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur floor traversing pay-offs meet the demands of heavy load carrying capacity and broad reel range due to extending production lengths. Due to its energy saving braking system, the pay-off reduces the overall power consumption of the production line. The frame design allows reel loading by an overhead crane.

The FPO 30 pay-off stand is a portal design floor traversing machine. The machine has two vertical stands with pintles. The stands are connected at the top by a horizontal telescopic shaft. Due to the telescopic function, the machine width is minimized. A separately quoted device is needed to control the traverse movement and the cable angle during the unwinding process.

The reel is rotated either by a tyre or by a carrier arm, depending on the customer need. When the reel is rotated by a tyre, it is pressed against the reel flange with a spring set with an adjustable pressure. The wheel drive eliminates the need for a dog pin and the need to change gears. This allows the load/unload sequence to be automated. If the reel is rotated with the dog-pin and the carrier arm, higher cable tension can be achieved.

Before reel change, the reel diameter can be preset from the control panel to correspond to the next reel diameter. The reel rotation can be either torque controlled with winding radius compensation or speed controlled (dancer, accumulator or external reference). Automatic positioning of the carriage from the loading position to the production position and vice versa can be activated from a button. The full reel moves automatically to the reel change position. The reel is lowered and the pintles are opened. After the pintles have been manually entered into the empty reel, another button is pushed, and the reel is lifted and moved to the working position.

A pair of pintles is delivered with the machine as standard.

Brushless AC motors, contactless proximity switches and solid state electronics increase reliability and ease maintenance.

All functions, like reel rotation, traversing and pintle movements, are activated and controlled either from a hanging panel or from a fixed place. The control panel has push buttons and potentiometers for manual or automatic running and a multilingual information display for machine status, settings and alarms.

| Reel weight, max. | 30 000 kg |

| Reel flange diameter, max. | 5000 mm |

| Reel width, max. | 3000 mm |

| Cable diameter, max. | 120 mm |

Exact values depend on the assembly.

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more