Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

Phipps Bend Industrial Park<br />

402 Phipps Bend Road

TN 37873 Surgoinsville

Tel: +1 423 817 2440

Fax: +1 423 212 0131

om;a.c;rus;efe;ill;/ma;jonMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troHigh speed and uninterrupted continuous wire unwinding with constant tension will maximize productivity of insulation line.

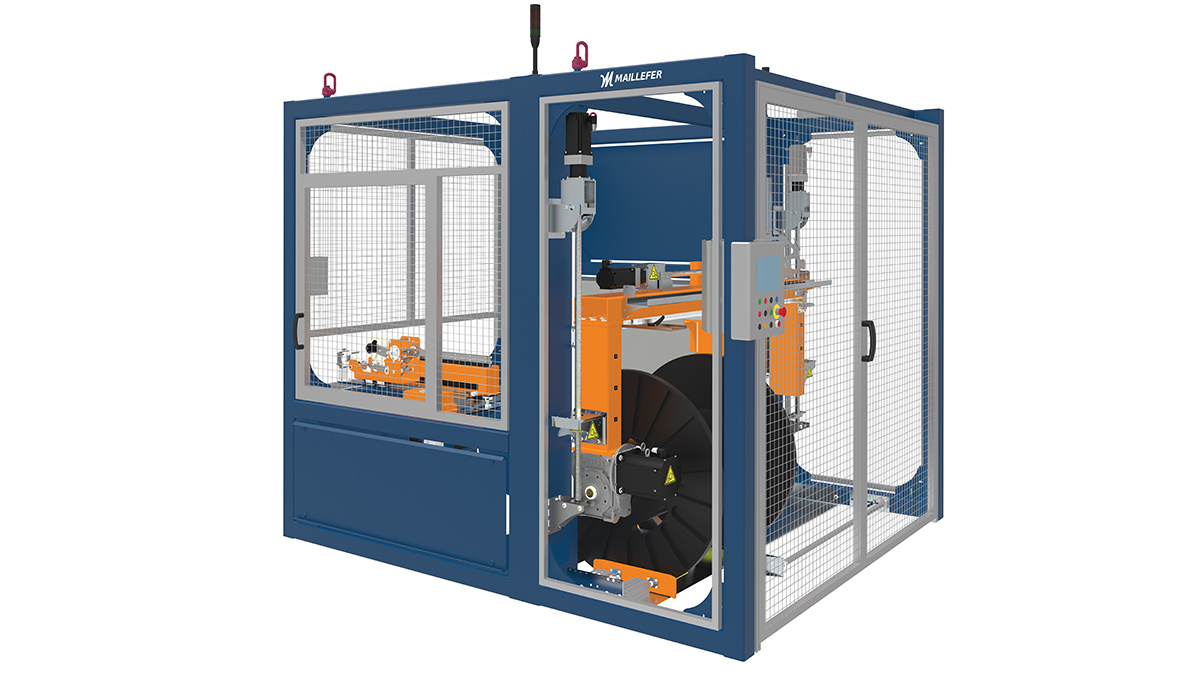

Our Flyer Pay-off KR 630 is designed for continuous, silent and smooth flow of wire at high production speeds. Special attention has been paid to the design of the fly-off cone geometry in order to minimize stress on the wire when paying-off at high speeds. This has resulted in an egg-shaped cast iron cone. As an extra benefit, low noise level is achieved due to the good noise absorbing characteristics of cast iron.

The pay-off comprises of two cast iron cones. The inside surface of the cones are machined and have a longitudinal slot on one side to enable wire fly-off change over from one cone to the other for continuous production. Each cone has a reel holder with a driven shaft. The reel holder hangs on the cone to free the loading trolley. Included in a basic machine is one pair of fly-off flanges for each reel size and one pair of reel shaft adapters for one reel centre hole dimension. A central wire guide is also included. If needed, one wire clamp on each cone can provide the change over information.

| Reel weight, max. | 500 kg |

| Reel flange diameter | 630 mm |

| Reel width | 475 mm |

| Cable diameter, max. | 0.3 - 2.8 mm |

| Reel rotation speed, max. | 800 m/min with 0.2 mm single wire |

Exact values depend on the assembly.

17.7.2024

The KWS, KWI for profile, and TUT join the family of coilers / reelers / take-ups best suited for winding pipe, tube and profile. They offer the right fit for the right job. Read more

10.7.2024

This new compact take-up is designed especially for small fiber optic jacketing lines. The machine is optimized for light weight and flexible products like drop cables and premise cables. Read more

10.7.2024

Maillefer is proud to drive changes taking place in our industry. It feels like magic, filled with excitement, when innovations are at their best! Master more with less. Read more

3.7.2024

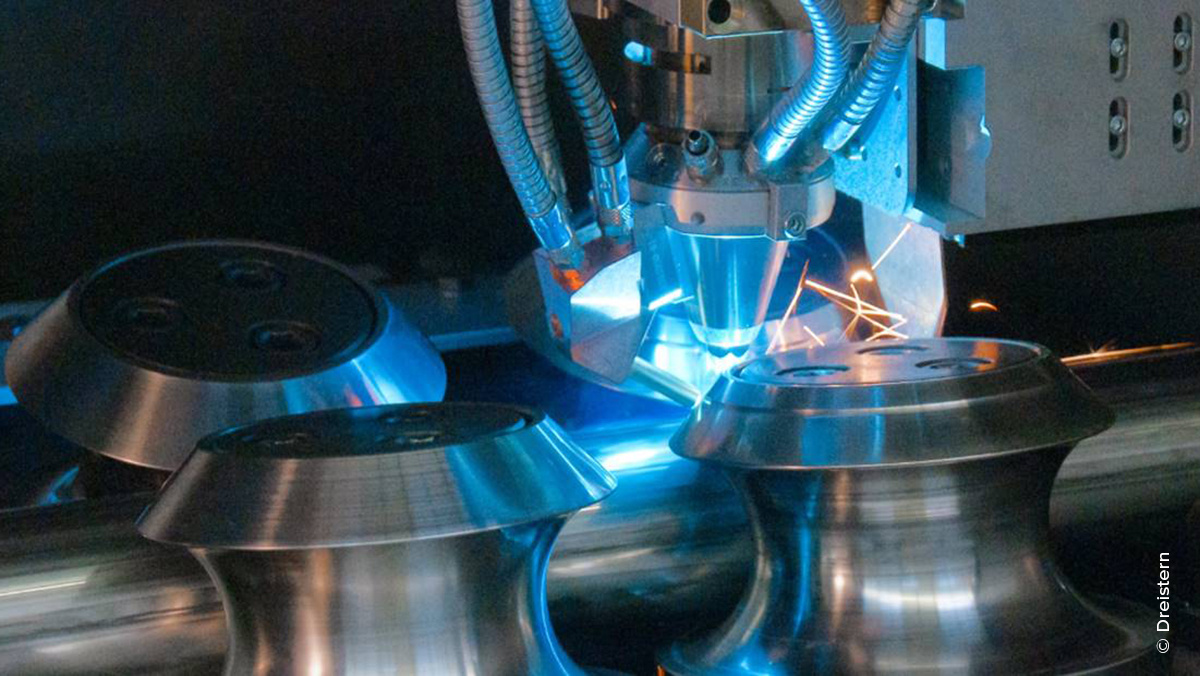

Maillefer proposes both aluminum butt welding techniques in its offering. Ultimately, it’s the customer’s local conditions and particular situation that helps make the choice. Read more

19.6.2024

An extrusion process involves various factors to minimize environmental impact and resource consumption. Maillefer favors exchange that focus on maximizing efficiency. Read more

12.6.2024

Critical S5 PLC components are proving to be nearly impossible to find anywhere on the world’s markets. Are you ready to face the increasing probability of a breakdown? Read more

6.6.2024

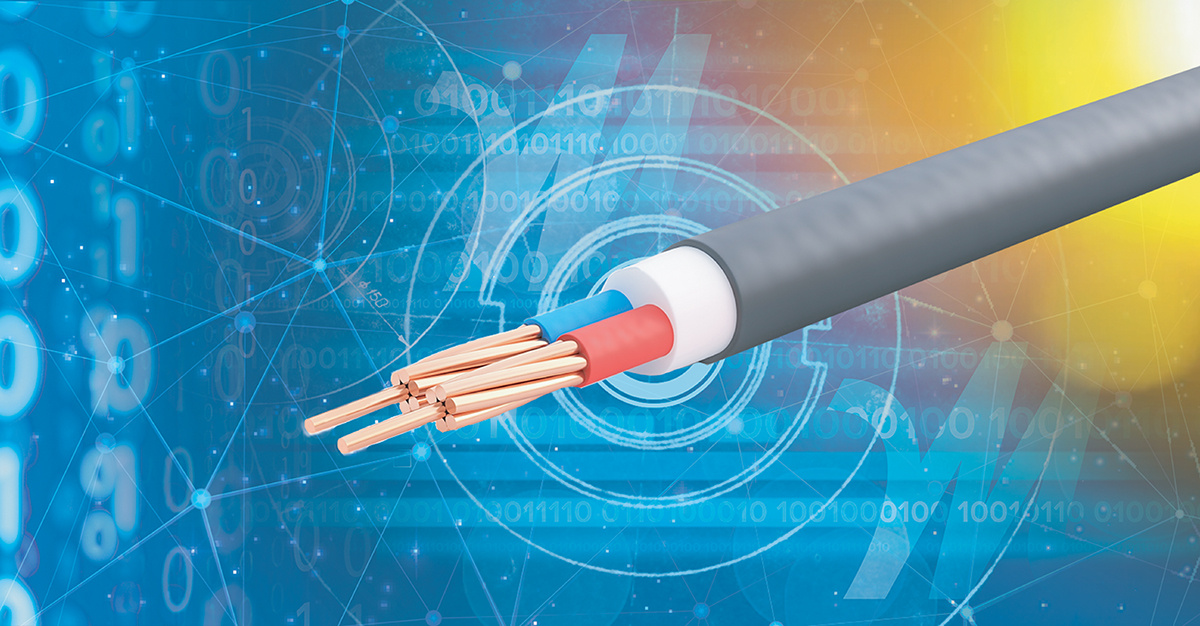

Stack-up your chances when co-extruding. Formulations and rheology are a moving target. An analytical approach means offering more than just extrusion equipment. Read more

29.5.2024

Be ready with this perfect solution for medium- and high-voltage PP insulated cable production. Short residence times and streamlined flow channels are just the beginning of what this crosshead offers. Read more