Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troA well-controlled cooling secures that the conductor temperature at the end seal when the insulated core comes out from the pressurized curing tube is low enough and the generation of voids is prevented.

In the Open Water Cooling Circulation OWCS water is pumped from the unpressurized water tank through the heat exchanger to the end of the cooling tube. Thus the cooling operates by a counter-flow method.

In the beginning of the cooling tube, water flows back from the water trap to the unpressurized water tank through a control valve, which controls the amount of water in the water trap. This design ensures that there is always water in the touchdown area, and that the cooling section is always filled with water.

There is a water detector in the neutral tube, which prevents water from entering into the curing section by stopping the water circulation pumps and alarms the line control.

The water circulation unit includes two water circulation pumps, a heat exchanger and the necessary valves.

The piping is made of stainless steel and includes water circulation pipes, valves and flexible hoses.

The unpressurized water tank is not included in the standard delivery (optional). Maillefer will give a main dimension drawing of the tank to the customer. The tank must be equipped with a cover and a ventilation. The water space is separated with a filter mesh, into a clean and a dirty side. By-products can be easily removed from the open tank.

Water circulation unit

The water circulation unit consists of two pieces of water circulation pumps (one is spare), a plate type heat exchanger, necessary valves and instruments.

All these components have been installed on the same frame, which forms one complete unit. The water circulation unit is ready-fitted and completely tested.

Water trap for CCV line

The water trap for CCV line is equipped with a lid including a sight glass, a by-product outlet and a level sensor with a magnetic display controlling the water level height in the water trap.

| Circulation pumps | 50 Hz, 30 kW (25 bar) |

| Pump output | 60 Hz, 16 m3/h / H=208 m (20 bar) |

| Heat exchanger type | Plate |

| Heat transmission performance | 130 kW |

| Number of plates | 33 pcs |

Exact values depend on the assembly.

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

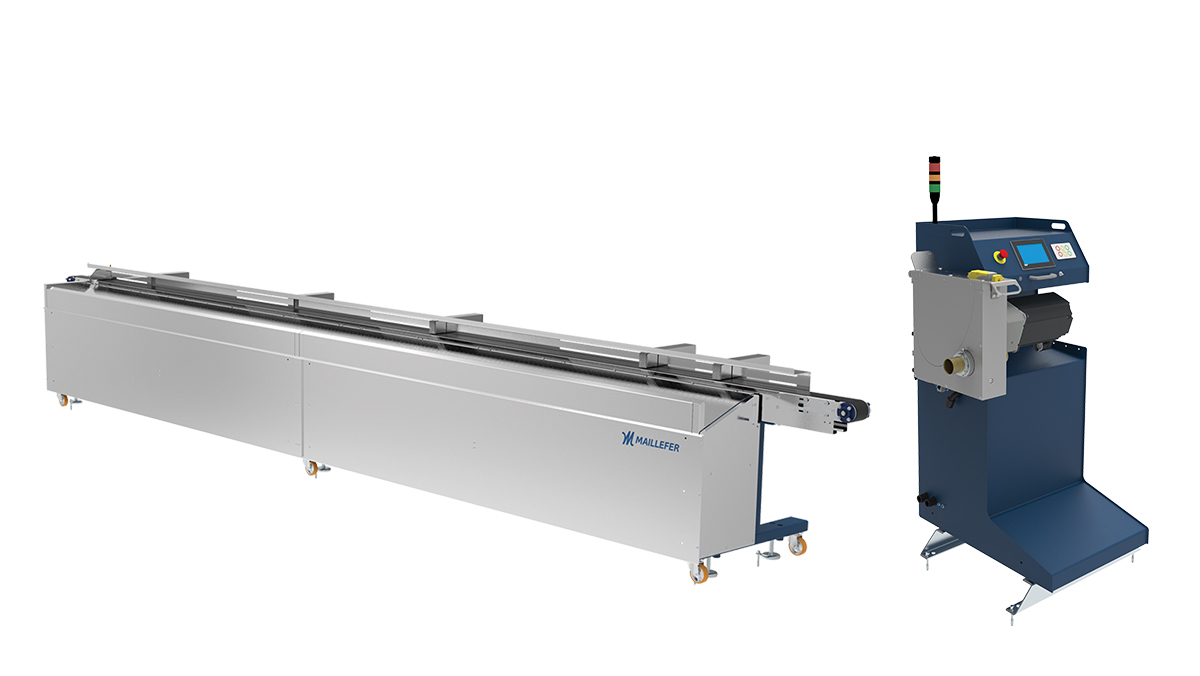

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more