Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

Phipps Bend Industrial Park<br />

402 Phipps Bend Road

TN 37873 Surgoinsville

Tel: +1 423 817 2440

Fax: +1 423 212 0131

om;a.c;rus;efe;ill;/ma;jonMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

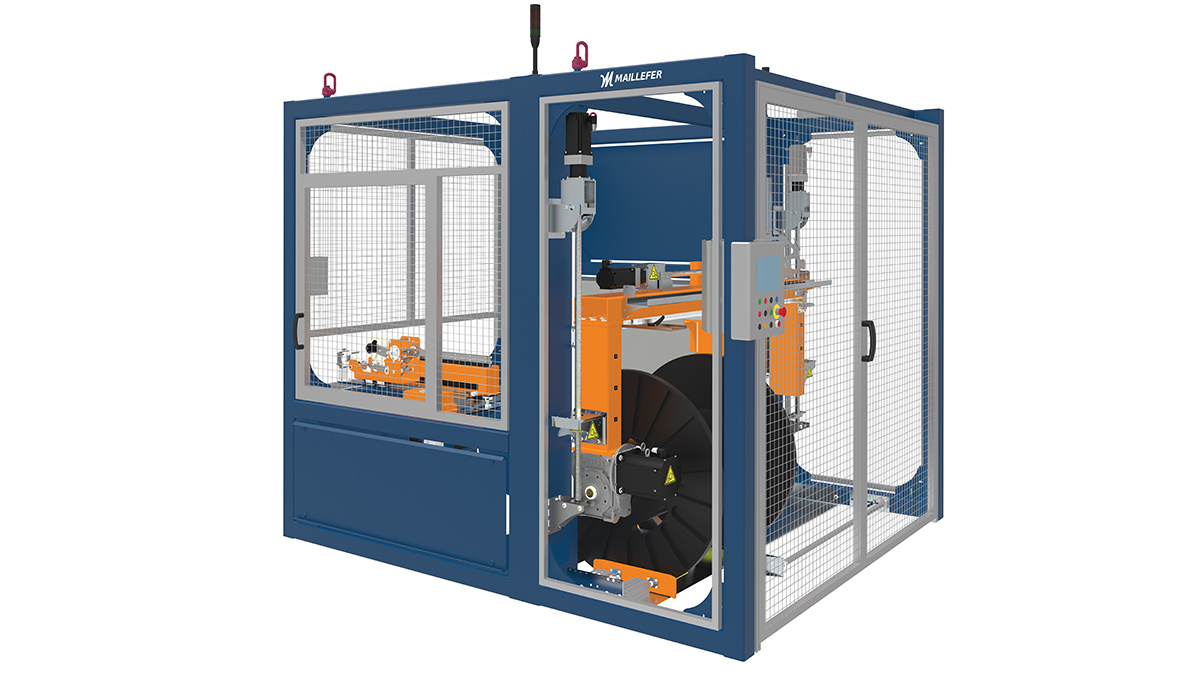

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur Portal Pay-off AVR 15 meets the demands of a heavy load carrying capacity and a broad reel range due to extending production lengths. The frame design allows reel loading from the rear or the front side of the machine. Different frame lengths and the possibility to mount on rails helps in reel logistics.

The pay-off has a hanging pintle portal design. The pay-off has two main components: the portal frame and the carriage. The telescopic lifting arms are suspended from the moving carriage, which is wheel mounted on the beams. All pintle movements, up down and in out, are motorized.

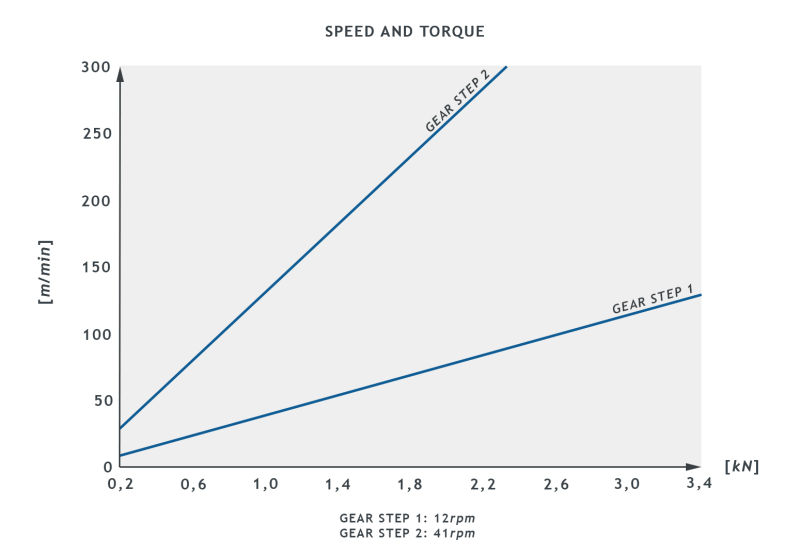

The reel is dog pin driven by a Vector controlled AC motor over a gearbox. The main motor can be run with a constant torque, or controlled by either a dancer or an accumulator. The motor has forced ventilation and is equipped with an electromagnetic brake. The brake can function as a holding brake or an emergency stop brake. One set of pintles is included in the machine price. Further sets can either be ordered from Maillefer or made according to the manufacturing drawings, which are enclosed in the manual.

All functions, such as reel rotation, traversing, pintle movements and auto reel handling, are activated and controlled from the hanging control panel.

CE approved

The pay-off beams are long enough to allow the carriage to traverse over the reel width. The carriage traverses during operation to maintain a near straight centerline of the cable. A separately quoted device controls the traversing of the reel.

An automatic positioning of the carriage from the loading position to the production position and vice versa can be activated by pressing a button. The full reel moves automatically to the reel change position. The reel is lowered and the pintles are opened. After the pintles are manually entered into the empty reel, a second button is activated, and the reel is lifted and moved sideways to the working position.

The machine is surrounded with safety fences to protect the operator and outsiders from the moving and rotating parts of the machine. The manually operated turning doors on the rear and the sliding door on the front of the machine are equipped with electromechanical locks. The main motor and automatic functions cannot be started before all the doors are closed and locked.

The machine fulfils all EEC machine and electrical directives and is equipped with CE and EC Declaration of Conformity labels.

| Reel weight, max. | 15 000 kg |

| Reel flange diameter | 3600 mm |

| Reel width | 2160 mm |

| Cable diameter, max. | 120 mm |

| Reel rotation speed, max. | 235 rpm |

| Torque, max. | 11 600 Nm |

Exact values depend on the assembly.

17.7.2024

The KWS, KWI for profile, and TUT join the family of coilers / reelers / take-ups best suited for winding pipe, tube and profile. They offer the right fit for the right job. Read more

10.7.2024

This new compact take-up is designed especially for small fiber optic jacketing lines. The machine is optimized for light weight and flexible products like drop cables and premise cables. Read more

10.7.2024

Maillefer is proud to drive changes taking place in our industry. It feels like magic, filled with excitement, when innovations are at their best! Master more with less. Read more

3.7.2024

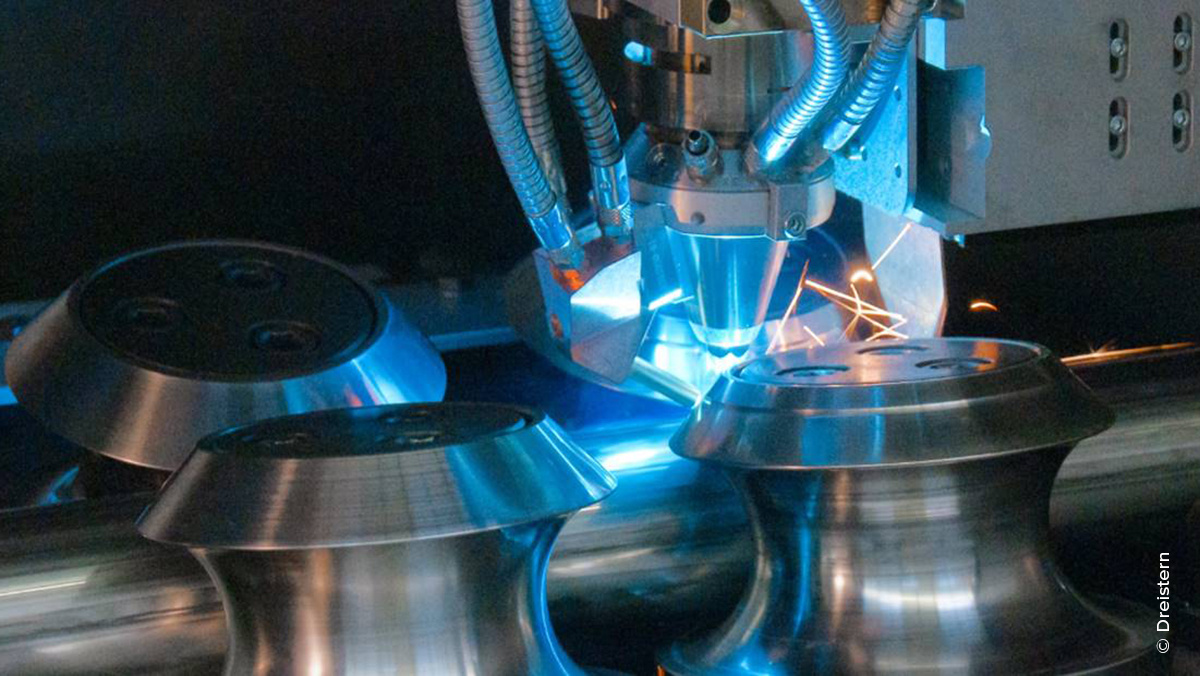

Maillefer proposes both aluminum butt welding techniques in its offering. Ultimately, it’s the customer’s local conditions and particular situation that helps make the choice. Read more

19.6.2024

An extrusion process involves various factors to minimize environmental impact and resource consumption. Maillefer favors exchange that focus on maximizing efficiency. Read more

12.6.2024

Critical S5 PLC components are proving to be nearly impossible to find anywhere on the world’s markets. Are you ready to face the increasing probability of a breakdown? Read more

6.6.2024

Stack-up your chances when co-extruding. Formulations and rheology are a moving target. An analytical approach means offering more than just extrusion equipment. Read more

29.5.2024

Be ready with this perfect solution for medium- and high-voltage PP insulated cable production. Short residence times and streamlined flow channels are just the beginning of what this crosshead offers. Read more