Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur crossheads have compact design and are very easy to handle and quick to assemble.

Our Triple Crosshead ECH 3/9 F main applications include insulation of telecommunication and data cable conductors as well as special wires with fluoropolymers. All parts of this head are made of corrosion resistant materials like inconel or stainless steel.

The crosshead has a manual centring system on the wire-guide adjustable at the back of the head. An additional manual centring system is provided to centre the incoming wire before it enters the wire-guide.

The standard head configuration allows triple layer extrusion of products such as skin/foam/skin. A number of other configurations and products are possible as well depending on the number of optional distributors included in the head. For skin/foam/skin products, a set of distributors is available to make both inner and outer skins with only one auxiliary. With other distributors, the number of layers can be reduced to two or one for extrusion of products like foam/skin, foam or solid insulation. All distributors of this head are conical shaped. The inner layer distributor is equipped with an internal heater.

The high performance and user friendliness of the head are achieved by combining smart design, close tolerances on all parts and unique geometry for each distributor.

| Cable diameter, max. | 9 mm |

| Entry diameter, max. | 3 mm |

| Weight | 10.6 kg |

| No. of temperature controlled zones | 3 |

Exact values depend on the assembly.

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

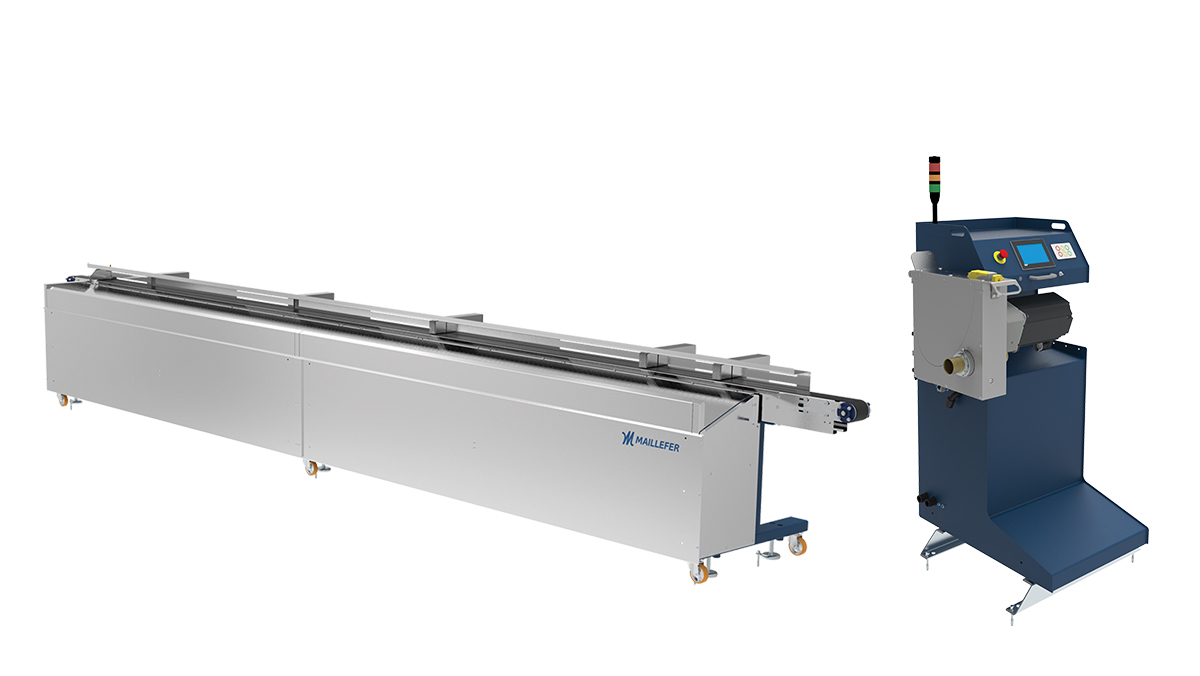

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more

20.3.2025

In the rapidly evolving field of optical fiber manufacturing, efficiency, precision, and quality are paramount. AI is in place to revolutionize the OF cable manufacturing process. Read more