Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur Triple Crosshead THX 35/75 MV ensures minimum material consumption and down time.

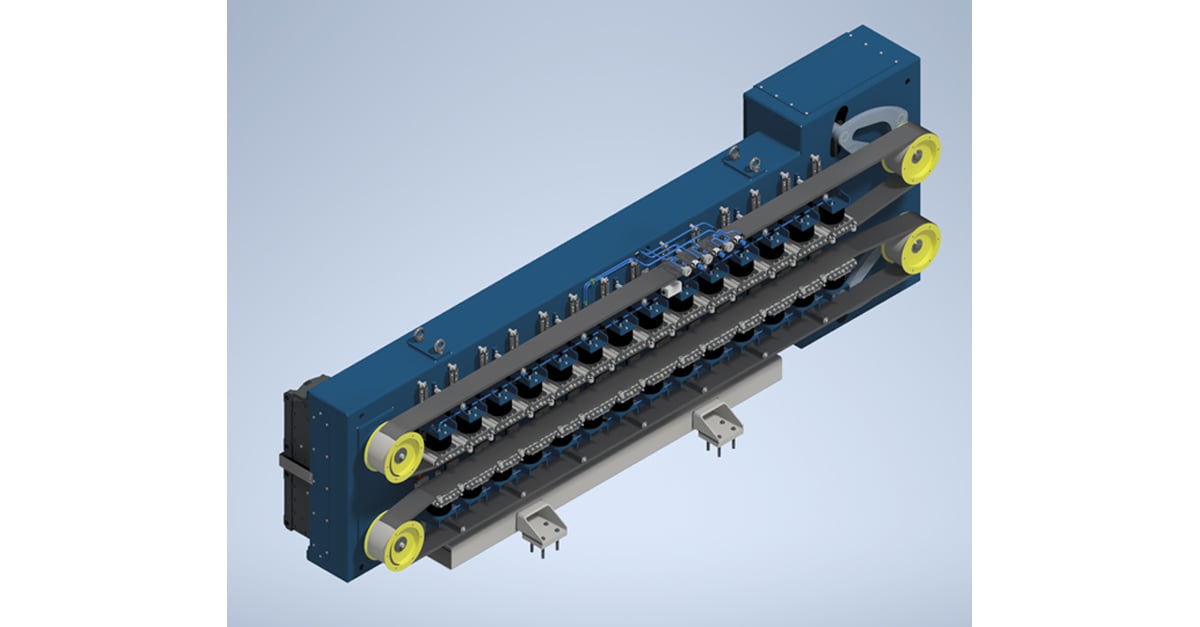

Our Triple Crosshead THX 35/75MV is used for a three-layer extrusion of MV XLPE and EPR cables. An additional flow distributor for EPR insulation is applied. The dimensioning of the flow channels ensures exact thickness for each layer.

The crosshead is equipped with Bi-Flow distributors. Bi-Flow technology in XLPE extrusion enables more accurate wall thicknesses and improved roundness of the cable. The head can be centred with zero screws prior to extrusion. Insulation and insulation screen layers can be adjusted independently. Centring can be repeated without touching the centring adjustment screws when the crosshead is dismantled. The connections between the crosshead and the extruders are fixed when the extruders are movable. This arrangement gives the operator optimum space for crosshead handling. The crosshead design allows a quick change of extrusion tools when the new cable dimensions are close to the ones presently used.

An independently controlled fluid circulation unit is used for the crosshead's temperature control. The heating capacity is at least 8 kW and the cooling capacity 5 kW at 120 °C.

| Conductor diameter | 4.0 - 35 mm |

| Conductor screen thickness | 0.3 - 2.0 mm |

| Insulation thickness | 1.0 - 20 mm |

| Insulation screen thickness | 0.3 - 2.0 mm |

| Weight | 350 kg |

| No. of temperature controlled zones | 4 |

| Heating of crosshead body | With oil or water |

Exact values depend on the assembly.

10.2.2026

For over 50 years, Maillefer has led Heating & Plumbing extrusion technology — delivering reliable, high-performance systems for modern, efficient production. Read more

29.1.2026

The 2026 Budget Law (Law No. 199 of 30 December 2025) introduces new hyper-amortization rules for investments in capital goods made between 1 January 2026 and 30 September 2028, in line with the Transition 4.0 and 5.0 tax credit frameworks. Read more

20.1.2026

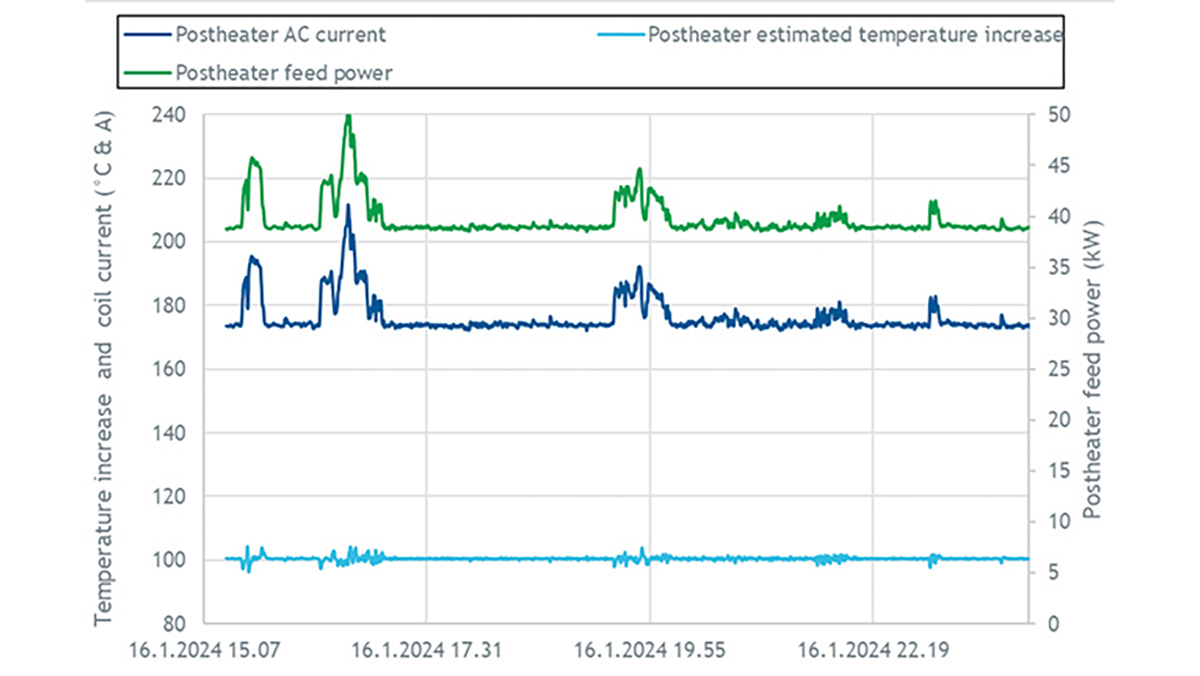

Move forward in curing optimization. Intelligent induction gets you consistent conductor temperature and superior cable quality. The system self-adapts to conductor temperature in real time. Read more

8.1.2026

Smarter upgrades mean stronger performance. Maillefer’s new KWB coiler and CMC cutter bring precision, safety, and efficiency to augment the potential of your extrusion line. Read more

18.12.2025

As cable sizes grow, Maillefer’s new heavy-duty caterpillars deliver unprecedented pulling power. Designed for the toughest cables, they boost traction, efficiency, and performance. Read more

15.12.2025

For 125 years, Maillefer has innovated in industry. From modest origins to a global leader, the company continues to drive technology, sustainability, and customer success. Read more

24.11.2025

12.11.2025

Vice President Philippe Moeschler shares insights on innovation, sustainability, and customer care as Maillefer showcases its latest technologies at K 2025. Read more