Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;tro

Maillefer works as your responsible partner for all planning, building, technology and engineering tasks until the start-up of new production lines, and quality and information systems. You get profitable production from the start, you need minimal own resources and you outsource the risk in investment planning and realization.

Excellence in demanding project executions, product quality and advanced production technologies has always been our key priority. More than 80 plant definition studies and more than 4000 line deliveries are our proof of competence in realizing business ideas into profitable factories.

You have noticed the emerging demand for certain cables, but are unable to meet it with your current production. You might also need more information on the lifetime of the new investment. This is where Maillefer Factory System could be the right way to proceed.

We find the most profitable and sustainable production solution to complete your feasibility study. Our Plant Definition Study gives you a view on raw material flows, cable constructions, needed production processes and machinery, the main operational requirements and implementation schedule, and the size of the investment. An initial factory layout and utility consumption calculation are part of the study. Read more

When you have got the investment decision, we can start the project. You get a dedicated project manager who is your responsible contact until production start-up. At this point, architectural design and building tasks are specified, and your factory is taking the actual shape. We can also assist you in finding the local main designer. You have all the documentation needed for the building permit application. Read more

After receiving the building permit, civil engineering starts with the full speed. This is the point where you need to make the initial investment for equipment.

Now it is time to realize your factory plan within your investment budget. We manage the project on your behalf regarding all equipment needed for production. Once the building is ready, the implementation schedule can be secured by our project management excellence. Read more

In each delivery, the production set-up is done by us to guarantee that you get the expected performance and productivity in the predefined time. We ensure that your quality system is compliant with standards. The best industrial production practices are applied on your factory.

Read more on Technology Transfer

Read more on Quality System

As part of the factory delivery, we optimize your central production processes and parameters. Partnering with our maintenance and performance solutions keeps your cost, product quality and productivity at the expected level over time. Read more

14.7.2025

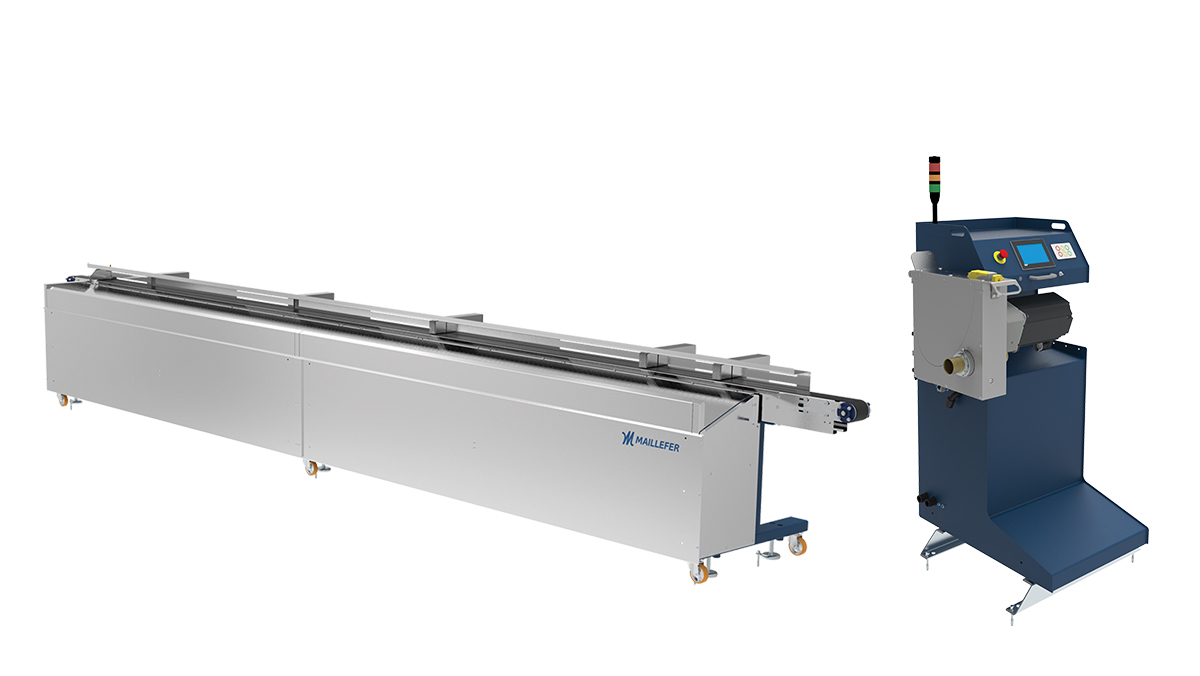

Here is a robust cutter for your larger extruded pipes. Our CMC 75 is designed to cut rigid multi-layer PO, PEX, and PE-RT pipes into bars. Achieve precise cuts, each and every time. Read more

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more