Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur Line Control Autocure 4.1 ensures optimum capacity and high dilectric strength with minimum production cost.

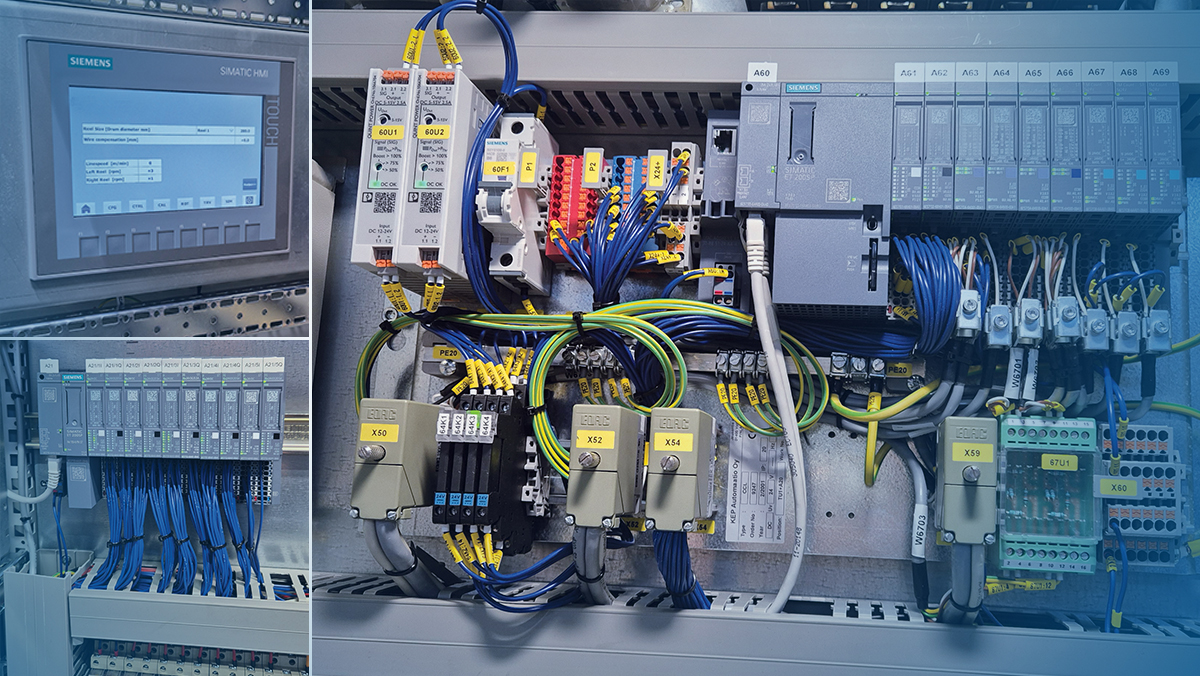

Our Line Control Autocure 4.1 consists of a Line Control Unit (LCU) with a fail safe PLC, an industrial field bus for controlling distributed I/O and drives, a user friendly movable control panel with a Siemens touch screen, a NOMOS Process Supervision Unit (PSU), an Uninterruptible Power Supply (UPS) for PSU (5 – 10 minutes), and a remote PSU unit.

Process sequences

The LCU hardware is based on the Siemens PLC. The software contains all logical sequences and calculations for performing. The process sequence control function is an important benefit, which ensures high cable quality during ramps maximizing the amount of quality cable from start to finish of the process and reducing the need for operator supervision. To initiate process sequences, the operator only has to click the corresponding button, the alternatives being START (slow speed), PROD (production speed), SLOW (e.g. for reel change), and END (automatic after curing and cooling). Synchronization of all machines is based on an actual process sequence phase. The line control also takes care of the extruder and tube heating temperature, as well as the logics and interlocking of machines, valves, pumps, and the system diagnostic of hardware modules and bus nodes.

The PSU consists of an industrial PC connected to a PLC and software developed for cable production supervision. The PSU's highly interactive interface ensures quick settings, high quality repeatable production, complete alarm control, controlled maintenance and historical reporting for production management. The PSU and its two flat displays is placed in a separate control room. One display is for normal operation while the other displays the process status.

The has PSU modular functionalities, such as process monitoring, an alarm system, production history, a recipe system, time based data logging, and areporting system. The PSU Remote Control Unit can be placed in a comfortable location on the line. It includes a touch PC and it functions in parallel with the PSU computer.

Remote service

The remote service connection is made in a secure way via internet or GPRS/EDGE connection. It gives the possibility to make remote service, diagnostic, software update and troubleshooting functions for the line automation system, almost in a similar way as with a local connection. The remote service includes the required hardware and the functionality tests of the connection. If the GPRS/EDGE connection is used, the customer must provide the required SIM-card. The price of the remote service is negotiated case by case.

29.1.2026

The 2026 Budget Law (Law No. 199 of 30 December 2025) introduces new hyper-amortization rules for investments in capital goods made between 1 January 2026 and 30 September 2028, in line with the Transition 4.0 and 5.0 tax credit frameworks. Read more

20.1.2026

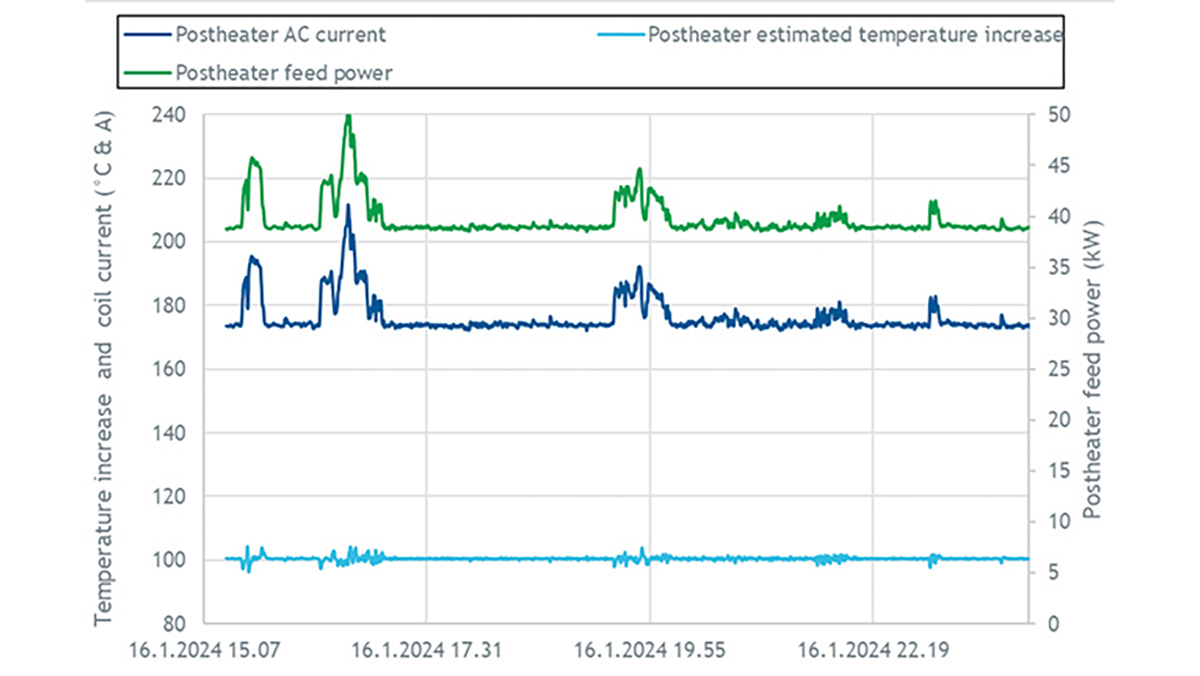

Move forward in curing optimization. Intelligent induction gets you consistent conductor temperature and superior cable quality. The system self-adapts to conductor temperature in real time. Read more

8.1.2026

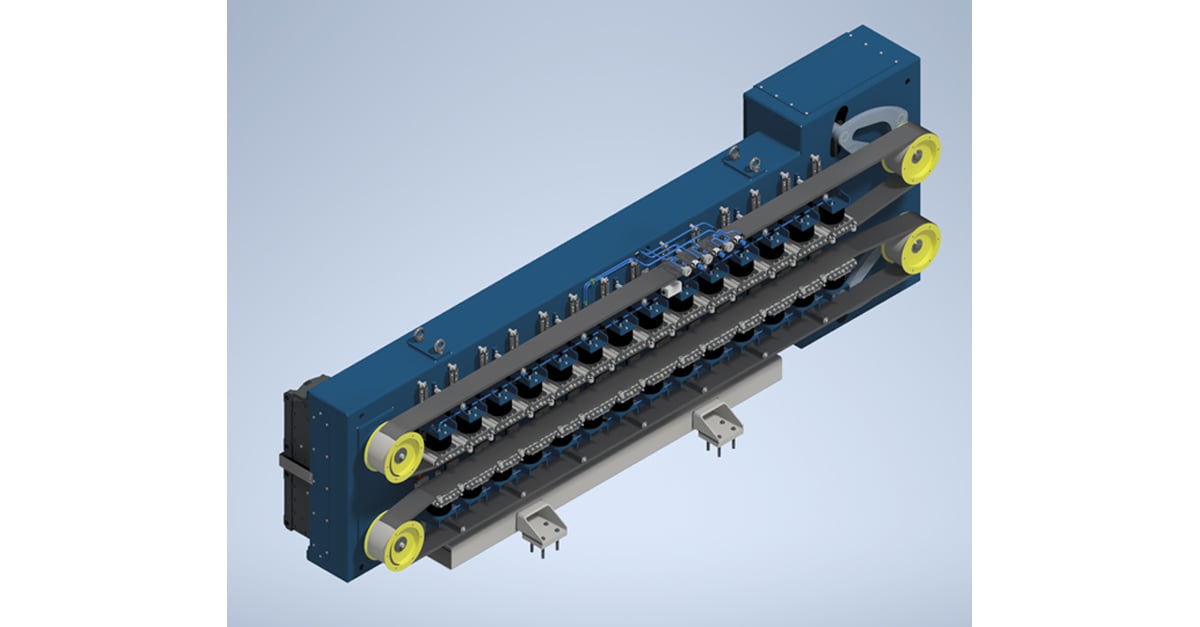

Smarter upgrades mean stronger performance. Maillefer’s new KWB coiler and CMC cutter bring precision, safety, and efficiency to augment the potential of your extrusion line. Read more

18.12.2025

As cable sizes grow, Maillefer’s new heavy-duty caterpillars deliver unprecedented pulling power. Designed for the toughest cables, they boost traction, efficiency, and performance. Read more

15.12.2025

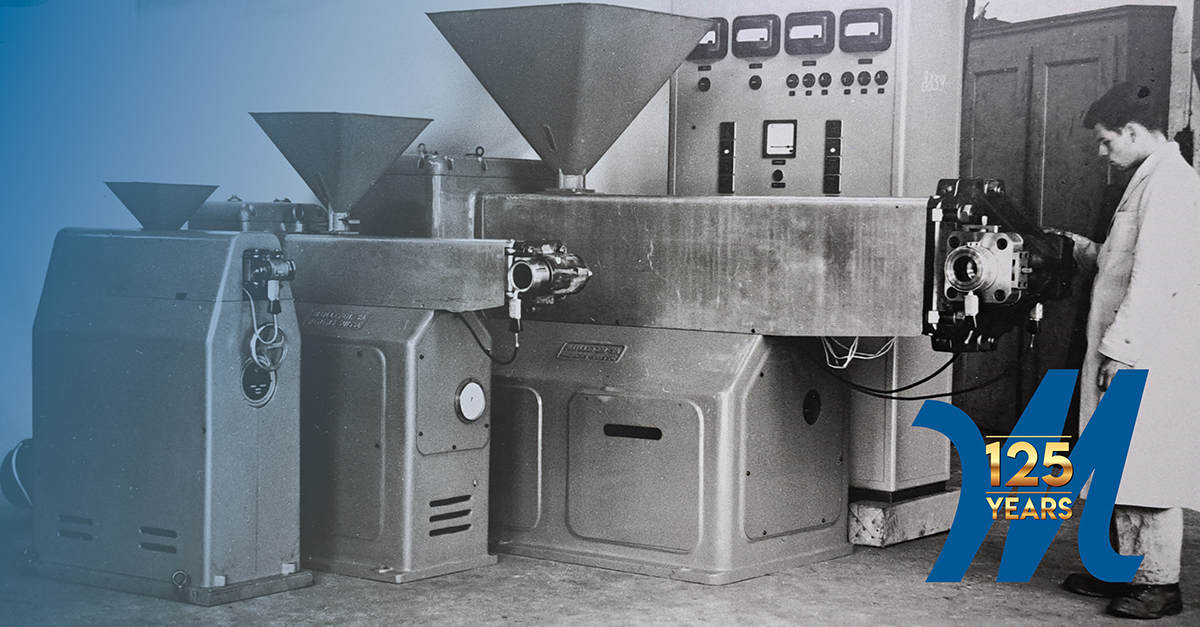

For 125 years, Maillefer has innovated in industry. From modest origins to a global leader, the company continues to drive technology, sustainability, and customer success. Read more

24.11.2025

12.11.2025

Vice President Philippe Moeschler shares insights on innovation, sustainability, and customer care as Maillefer showcases its latest technologies at K 2025. Read more

7.11.2025

Replace the outdated analog cards of your durable EKP take-up. Overcome the maintenance challenge. Our PLC replacement kit helps you ensure the move to the digital world. Read more