Nearest Maillefer contacts for USA

Maillefer North America

Pipe & Tube

#1 Extrusion Drive<br />

CT 06379 Pawcatuck

Tel: +1 860 625 48 45

com;rd.;nda;sta;is-;dav;uk/;jwnMaillefer North America

Wire & Cable

#1 Extrusion Drive

CT 06379 Pawcatuck,

Tel: +1 920-215-6628

om;d.c;dar;tan;s-s;avi;w/d;cho;jzaKN Manufacturing Solutions LLC

Fiber Optic

325 Kentucky Court

GA 30548 Hoschton

Tel: +1 404 202 9655

Cell: +1 404 202 9655

com;ol.;nms;n/k;ine;iem;i.n;karAmaral Automation Associates

Wire & Cable

1697 Warwick Ave, Suite D

RI 02889 Warwick

Tel: +1 401 405 0755

om;n.c;tio;oma;aut;ral;ama;es/;salRepco Industries LLC

Wire & Cable

13299 W. Essex Ln.

Illinois 60142 Huntley

Tel: +1 847 802 4315

Cell: +1 847 274 9218

com;es.;tri;dus;oin;epc;s/r;otu;nliSouthern Industrial Equipment

Wire & Cable

2708 Cambridge Way

TX 75092 Sherman

Tel: +1 281 844 4260

Fax: +1 903 813 0285

net;ns.;tio;olu;ons;usi;xtr;y/e;troOur line control software are advanced, modular and expandable control systems which provide structured and user friendly ways to operate, control, monitor and manage your valuable production.

Our Line Control Autoextrusion 4.1 (AE 4.1) provides control of the extrusion line, monitoring of the machines, prodcution follow-up with an extended production management system and assures a user friendly operator interface. It enhances the productivity and reliability of the production line as well as the quality of the final product.

The AE 4.1 consists of Line Control Unit (LCU) with a fail safe PLC, an industrial field bus for controlling distributed I/O and drives, a user friendly movable control panel with a touch screen for NOMOS Process Supervisor Unit (PSU). The LCU hardware is based on a Siemens PLC. The software contains all logical sequences and calculations for perfoming, such as machines selection and interlocking, line sequences, synchronization of all machines, temperature control loops, system diagnostic of hardware modules and bus nodes.

The PSU consists of an industrial PC which is connected to a PLC and software specially developed for supervision of various cable type production. It is an easy tool for monitoring a process and adjusting it without long and laborious user training. The PSU's highly interactive interface ensures quick settings, high quality repeatable production, complete alarm control, controlled maintenance and historical reporting for production management. The PSU's modular functionalities include process monitoring, an alarm system, production history, a recipe system, time bases data logging, and a reporting system.

Remote service

The remote service connection is made in a secure way via internet or GPRS/EDGE connection. It gives the possibility to make remote service, diagnostic, software update and troubleshooting functions for the line automation system, almost in a similar way as with a local connection. The remote service includes the required hardware and the functionality tests of the connection. If the GPRS/EDGE connection is used, the customer must provide the required SIM-card. The price of the remote service is negotiated case by case.

14.7.2025

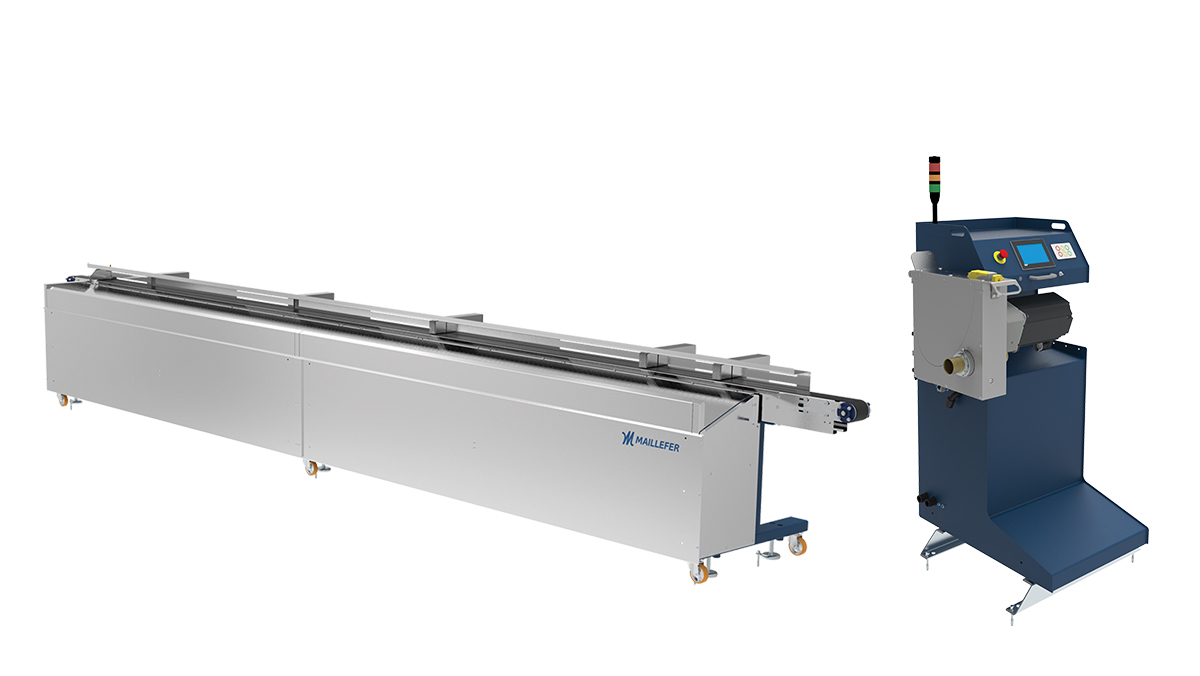

Here is a robust cutter for your larger extruded pipes. Our CMC 75 is designed to cut rigid multi-layer PO, PEX, and PE-RT pipes into bars. Achieve precise cuts, each and every time. Read more

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more