Maillefer's patented quick colour change system, X-flow, allows very fast insulation and striping color changes without stopping the production line. The color change system automatically changes the color with pre-defined lengths, which are determined by the built-in production scheduler in the line control.

With the X-Flow quick color change system there is no need to stop the line for insulation color changes. This helps improve your line productivity and it provides substantial cost savings, due to the reduced scrap rate.

10.2.2026

For over 50 years, Maillefer has led Heating & Plumbing extrusion technology — delivering reliable, high-performance systems for modern, efficient production. Read more

29.1.2026

The 2026 Budget Law (Law No. 199 of 30 December 2025) introduces new hyper-amortization rules for investments in capital goods made between 1 January 2026 and 30 September 2028, in line with the Transition 4.0 and 5.0 tax credit frameworks. Read more

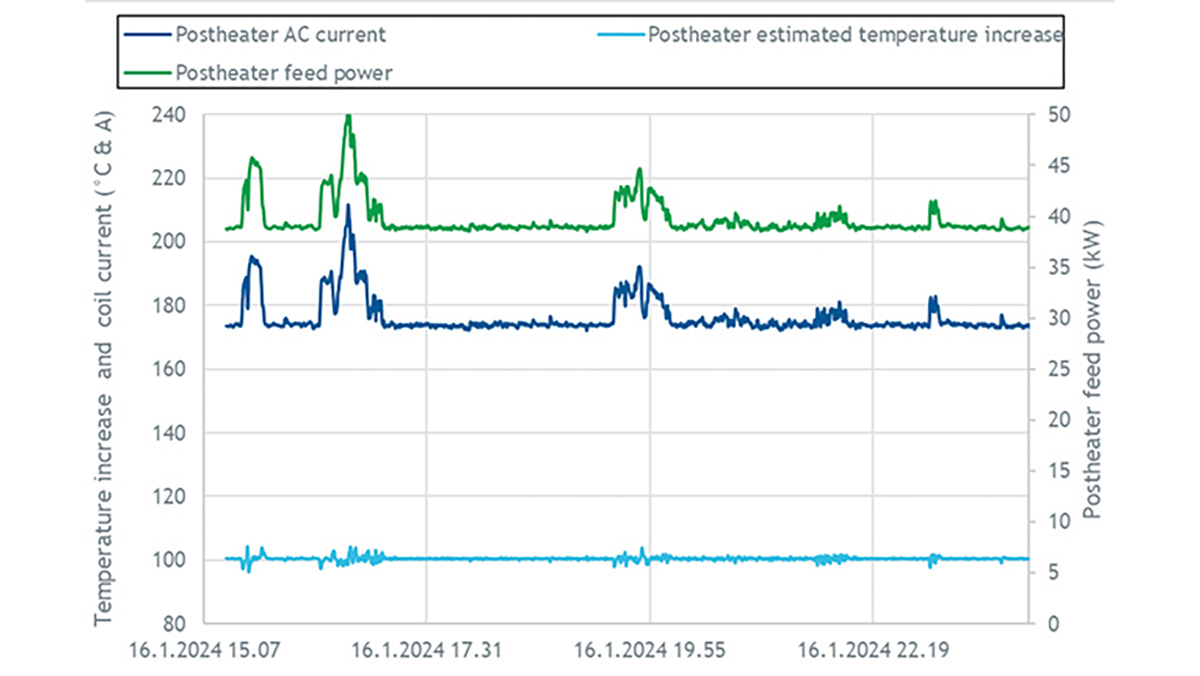

20.1.2026

Move forward in curing optimization. Intelligent induction gets you consistent conductor temperature and superior cable quality. The system self-adapts to conductor temperature in real time. Read more

8.1.2026

Smarter upgrades mean stronger performance. Maillefer’s new KWB coiler and CMC cutter bring precision, safety, and efficiency to augment the potential of your extrusion line. Read more

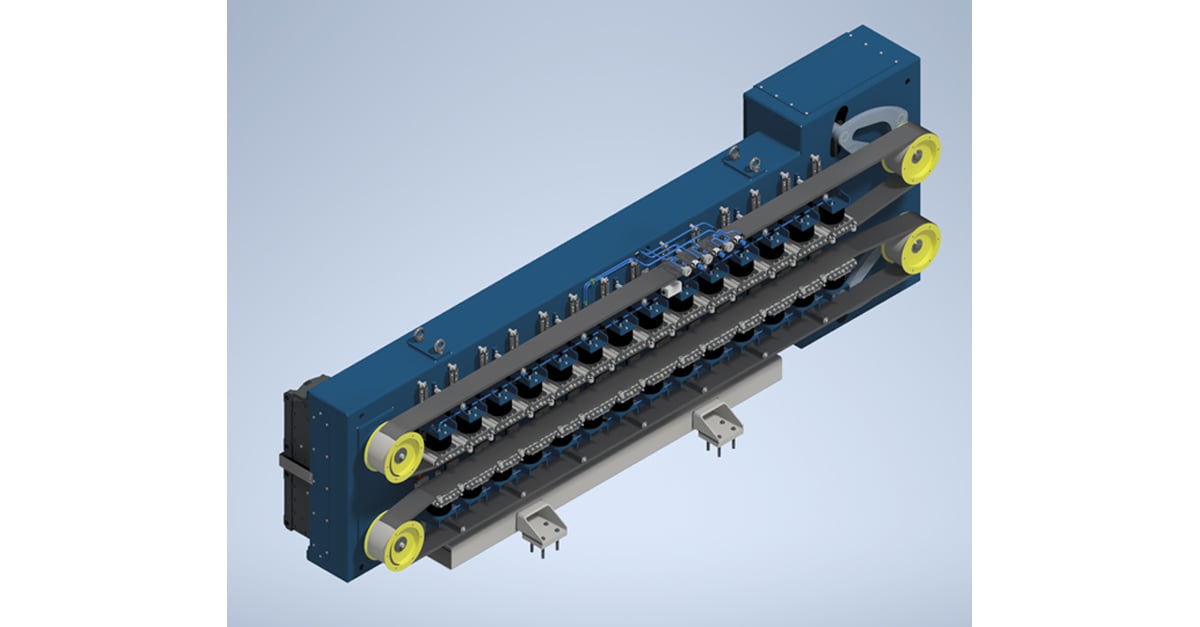

18.12.2025

As cable sizes grow, Maillefer’s new heavy-duty caterpillars deliver unprecedented pulling power. Designed for the toughest cables, they boost traction, efficiency, and performance. Read more

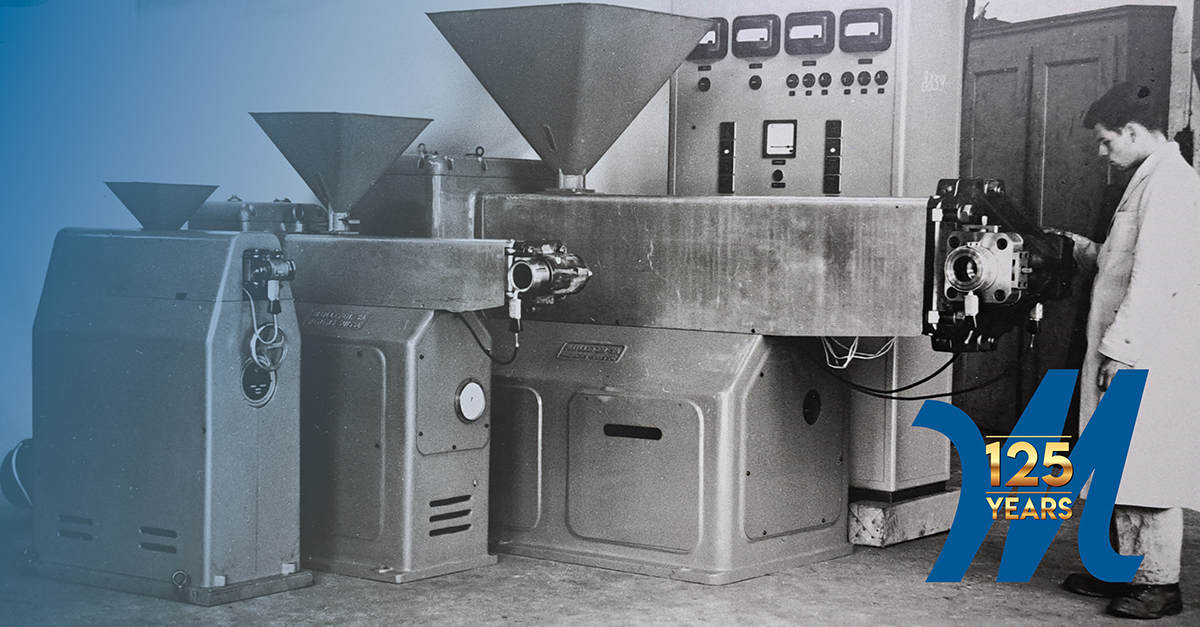

15.12.2025

For 125 years, Maillefer has innovated in industry. From modest origins to a global leader, the company continues to drive technology, sustainability, and customer success. Read more

24.11.2025

12.11.2025

Vice President Philippe Moeschler shares insights on innovation, sustainability, and customer care as Maillefer showcases its latest technologies at K 2025. Read more