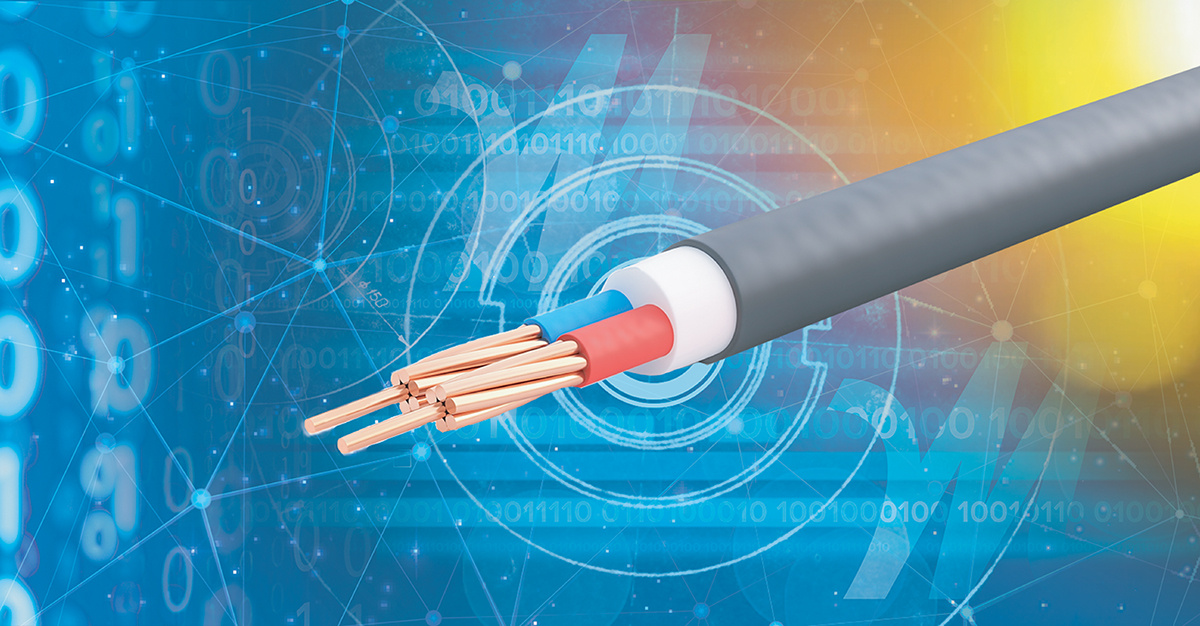

Maillefer's patented quick colour change system, X-flow, allows very fast insulation and striping color changes without stopping the production line. The color change system automatically changes the color with pre-defined lengths, which are determined by the built-in production scheduler in the line control.

With the X-Flow quick color change system there is no need to stop the line for insulation color changes. This helps improve your line productivity and it provides substantial cost savings, due to the reduced scrap rate.

17.7.2024

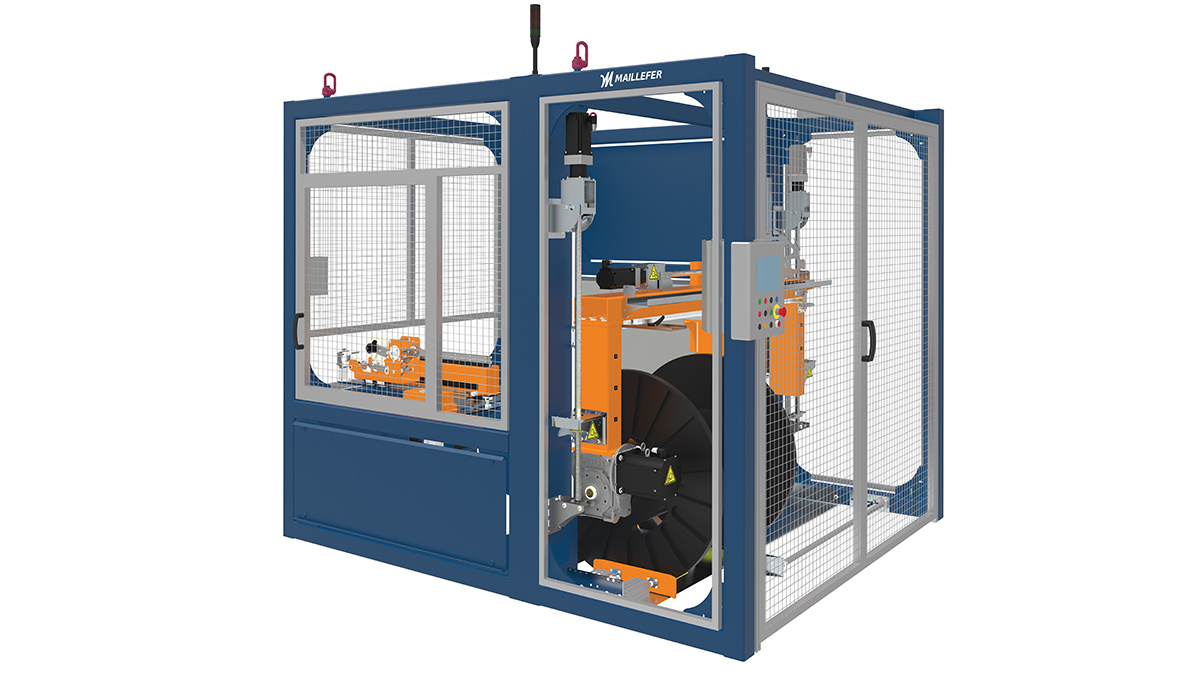

The KWS, KWI for profile, and TUT join the family of coilers / reelers / take-ups best suited for winding pipe, tube and profile. They offer the right fit for the right job. Read more

10.7.2024

This new compact take-up is designed especially for small fiber optic jacketing lines. The machine is optimized for light weight and flexible products like drop cables and premise cables. Read more

10.7.2024

Maillefer is proud to drive changes taking place in our industry. It feels like magic, filled with excitement, when innovations are at their best! Master more with less. Read more

3.7.2024

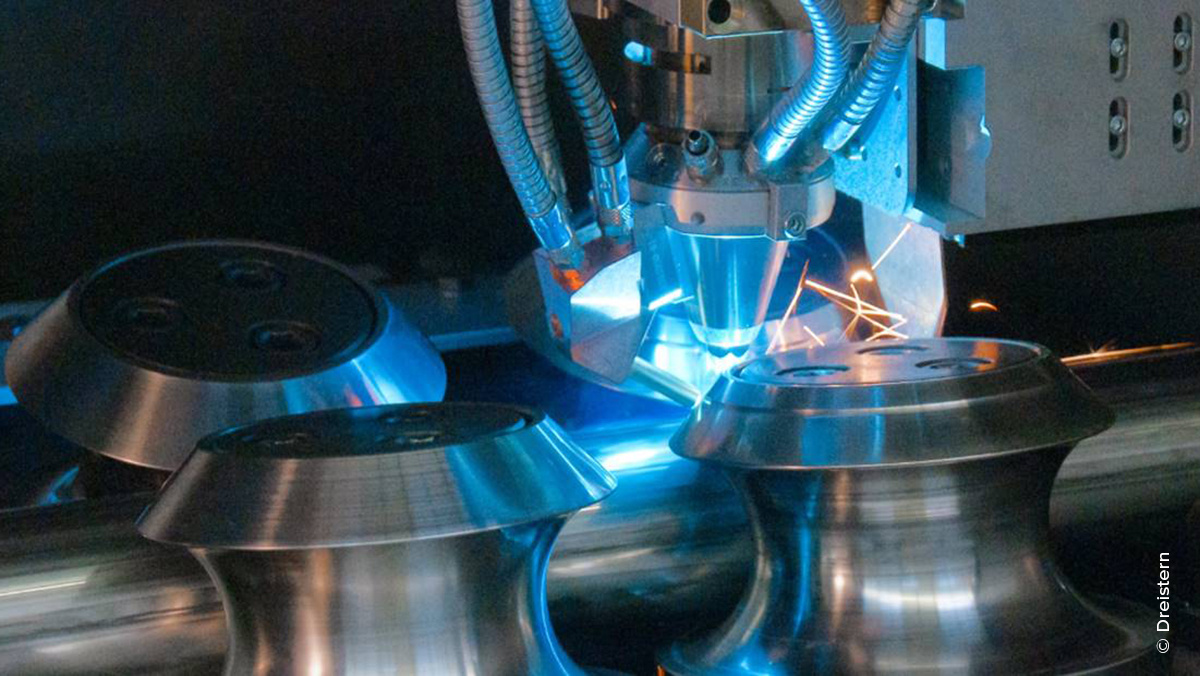

Maillefer proposes both aluminum butt welding techniques in its offering. Ultimately, it’s the customer’s local conditions and particular situation that helps make the choice. Read more

19.6.2024

An extrusion process involves various factors to minimize environmental impact and resource consumption. Maillefer favors exchange that focus on maximizing efficiency. Read more

12.6.2024

Critical S5 PLC components are proving to be nearly impossible to find anywhere on the world’s markets. Are you ready to face the increasing probability of a breakdown? Read more

6.6.2024

Stack-up your chances when co-extruding. Formulations and rheology are a moving target. An analytical approach means offering more than just extrusion equipment. Read more

29.5.2024

Be ready with this perfect solution for medium- and high-voltage PP insulated cable production. Short residence times and streamlined flow channels are just the beginning of what this crosshead offers. Read more